In response to the evolving infrastructure maintenance in Europe, Broshuis introduces a linkable axle solution. With lower axle loads permitted on an increasing number of roads and bridges, exemptions for certain routes are becoming more challenging. Broshuis’ linkable axle, a 1- or 2-axle bogie, can be connected between the dolly and the axle bogie of their pendulum axle semi-low loaders.

This innovative addition allows for a reduction in axle loads within the permit, providing greater flexibility for specific routes. It also proves advantageous when a multi-axle dolly is not always necessary, enabling normal transports without the linkable axle and adding it when needed. The first linkable axles have already been sold, converting a customer’s 10-axle (3+7) PL2 semi-low loaders into 12-axle (3+2+7) PL2 semi-low loaders.

The linkable axle can be seamlessly fitted to all new and existing heavy-duty pendulum axle semi-low loaders (100T Range) from Broshuis. The unique shape of the compression joints facilitates quick pin fitting and removal, allowing the (dis)connection of the linkable axle in as little as 15 minutes. This adaptability empowers operators to easily configure their combinations for specific loads, preparing their fleet for future demands.

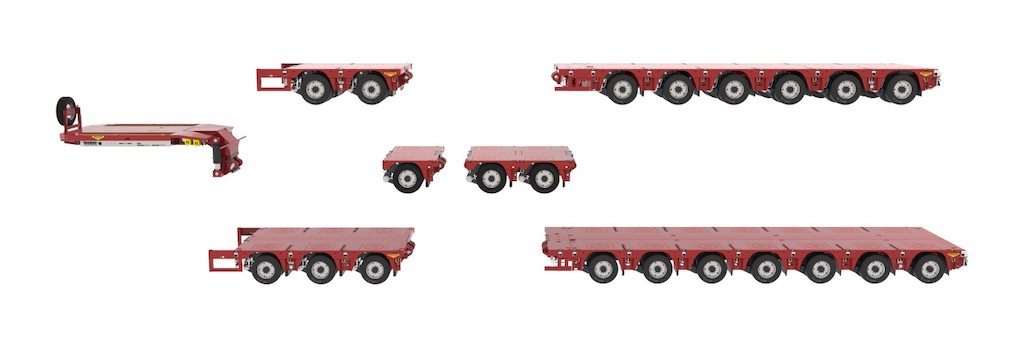

Broshuis’ 100T Range offers modular possibilities, with linkability among the neck, dolly, axle bogie, spacer, additional beam, and linkable axle. This flexibility enables the generation of additional prestressment. The 100T Range on pendulum axles includes single and double extendable 8-axle (2+6) and 10-axle (3+7) semi-low loaders, available in various configurations. With the linkable axle, operators can configure combinations in 2+6, 2+1+6, 2+2+6, 3+7, 3+1+7, and 3+2+7 formats.