Once more Allelys showcased its competence of delivering complex turnkey projects as they completed the transport and installation process of key equipment at the Lostock Sustainable Energy Plant located in Northwich. In this project, a steam turbine weighing 154-tonne and a generator weighing 132-tonne were taken from Ellesmere Port to the Power station site emphasizing the engineering techniques as well as logistical efforts which were put in place.

Using a shorter trailer configuration would have been opting for an easier option however the weight restrictions on the final approach meant that Allelys for the successive hauling of the turbine and generator had to use an 18-axle modular trailer . On reaching the site both parts were properly stooled off and kept aside for sorting until the following operation commences.

The generator was detached first since it had an in built loading capability and was mounted on a 10-axle SPMT which was then used to transport it around the location. A key challenge involved traversing a condenser pit, a task Allelys expertly managed by overbridging the area to ensure smooth movement.

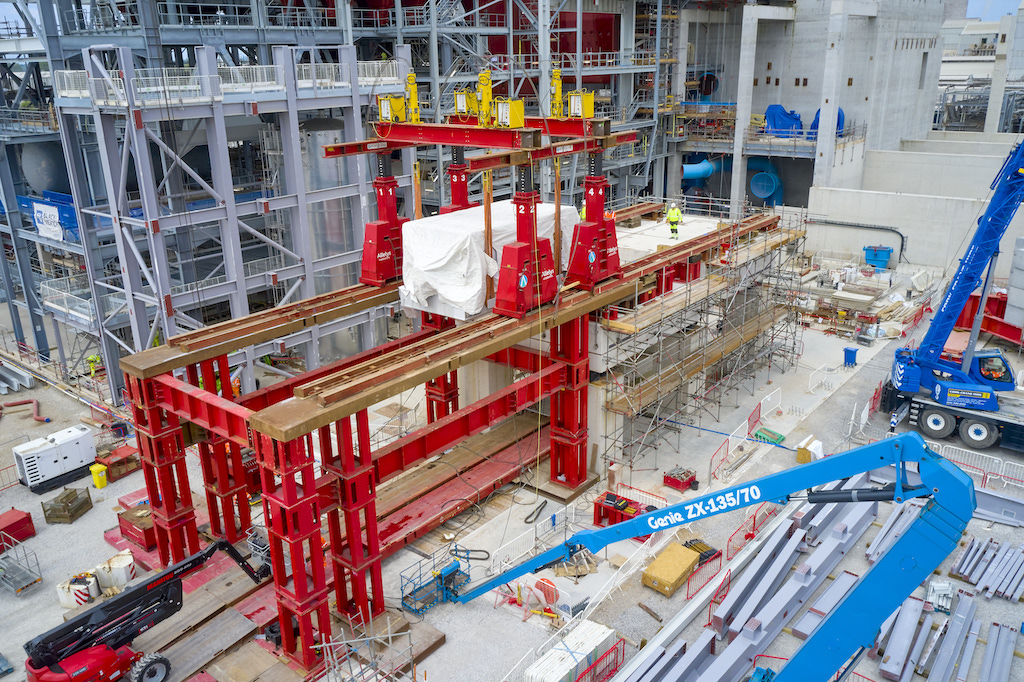

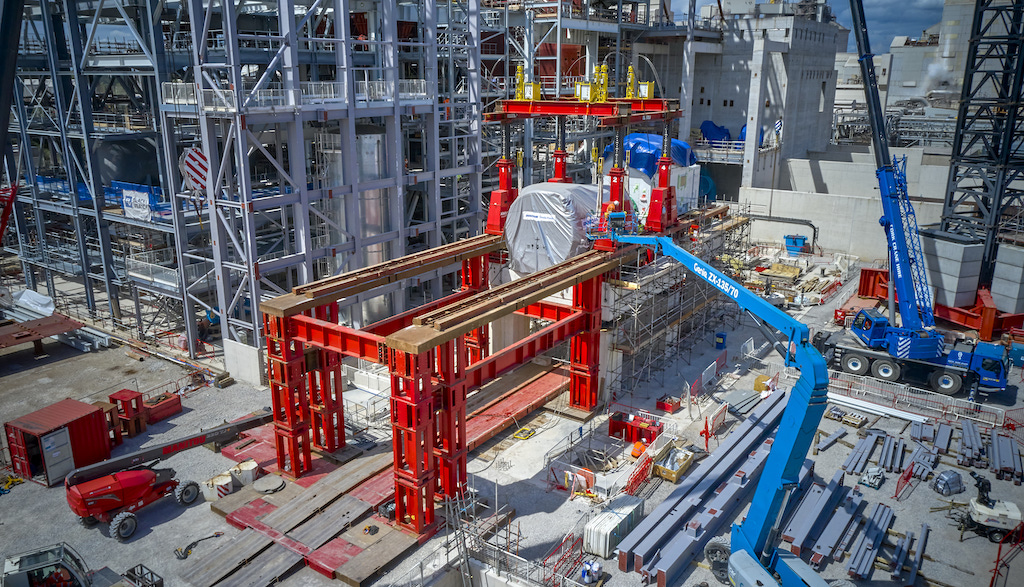

Once in position under the hydraulic strand jack gantry system, the generator was lifted to a height of 6.6 meters and then skidded approximately 20 meters to its final placement on the plinth. The steam turbine followed the same meticulous process: transferred onto the SPMT, positioned under the gantry, lifted, and skidded to its designated location.

“This project was a clear demonstration of the engineering capabilities within the Allelys business. Our engineering team developed a bespoke strand jack system design concept, and overbridging design, to ensure the successful delivery and installation of these critical components,” explained Garnaud Tsika, Commercial Manager at Allelys.

“We also showcased our agility and flexibility when faced with unexpected ground loading constraints on site. The site ground loadings were lower than what we were going to impose, however we re-engineered the project and by using additional equipment, we were able to adapt and meet the site conditions.”