Alevro, a joint venture between Australia’s Monadelphous and Italy’s Fagioli, has achieved a major milestone by completing the jack-down and installation of three massive LNG compressors at the Pluto LNG onshore facility in Western Australia. Using Enerpac’s EVO System, the operation combined advanced technology and innovative engineering to position the 3600-tonne compressors with precision and efficiency.

The Pluto LNG expansion, known as Train 2, will process natural gas from the Scarborough field in the Carnarvon Basin, 375 km off the WA coast. Once operational, the facility will add a capacity of approximately 5 million tonnes of LNG annually, reinforcing Australia’s position as a global leader in LNG production.

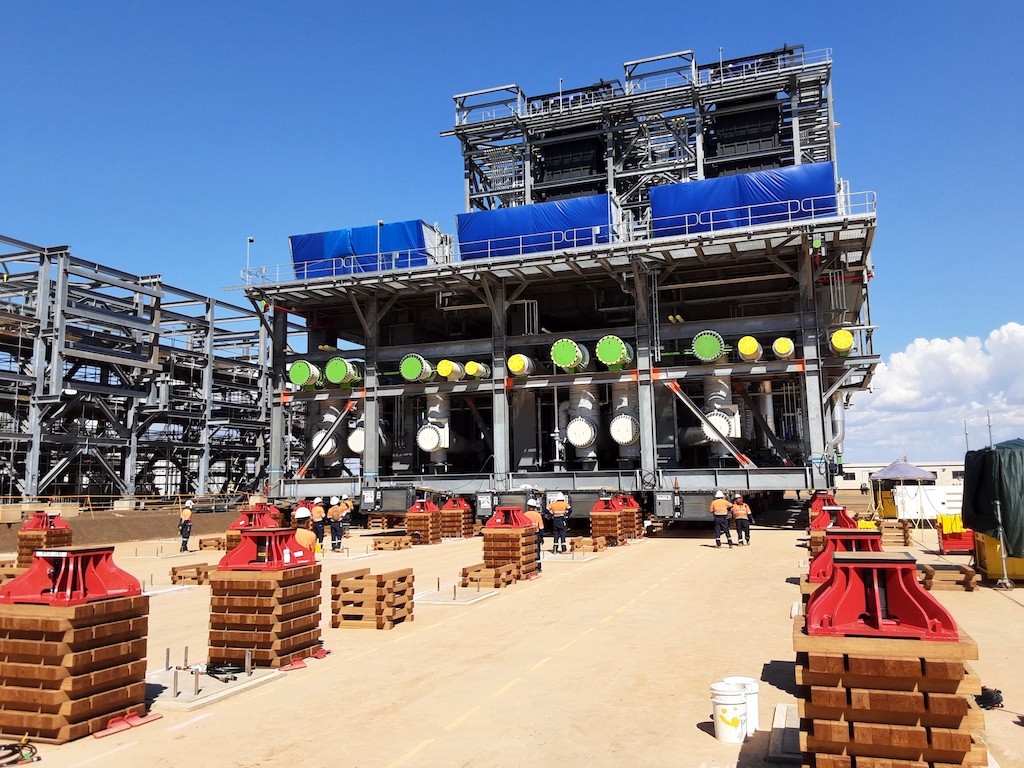

Alevro transported the compressors from the quayside to the installation site using Self-Propelled Modular Transporters (SPMTs) with 168 axle lines and eight power packs. The compressors, each measuring 63m long, 30m wide, and 30m high, were lowered onto pre-prepared foundations using Enerpac’s synchronous jack-down system.

The Enerpac EVO System featured 44 climbing jacks, each mounted on 1.2-meter-high stacks with an additional 500mm of frames holding Enerpac 250T jacks. Two Enerpac EVO power packs operated the system, managing 24 jacks on 12 hydraulic lines with a total power requirement of just 7.5 kW. This advanced system ensured precise load transfer and alignment throughout the process.

The project demanded extensive pre-planning and custom engineering. “Our first task was to perform the load-in operation of the compressors via SPMT transfer,” explained Tomasz Milewski, Engineering Manager at Alevro. “The Enerpac EVO ‘tilting mode’ was instrumental in aligning the module during the transition from the SPMT hydraulic bed to the climbing jacks.”

Operations Manager Massimiliano Vettrici emphasized the importance of testing and alignment:

“We ensured precise alignment during the lowering phase to avoid movement. The jack-down process proceeded smoothly, demonstrating the reliability of Enerpac’s technology and our execution methodology.”

Alevro’s groundbreaking approach has earned industry acclaim. The Crane Industry Council of Australia (CICA) awarded the project ‘Best Innovation,’ along with the People’s Choice Award for its creative and efficient execution.