Trelleborg Sealing Solutions has announced a major sustainability partnership with global steel company SSAB to integrate fossil-free steel in the production of damping shims for vehicle brake pads. This move marks a significant step toward reducing carbon emissions in the automotive industry, particularly in the rapidly growing electric vehicle (EV) sector.

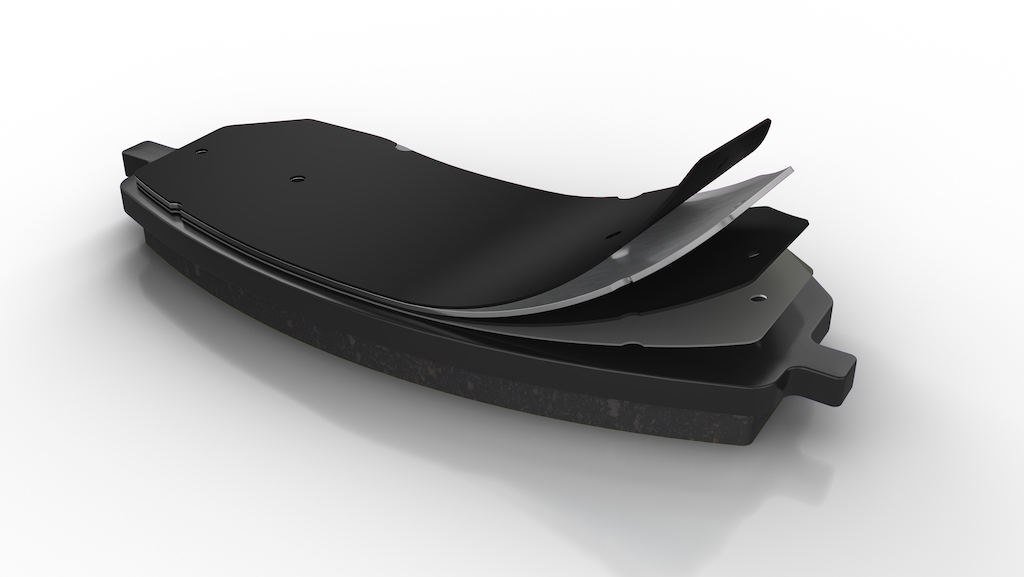

Damping shims, also known as anti-squeal plates, are essential components in vehicle brake systems. They eliminate noise and vibrations—a feature increasingly important in electric cars, which are quieter by nature. These shims are made by combining rubber, adhesives, and metal, and Trelleborg’s new partnership with SSAB will enable the company to produce them using more eco-friendly steel. This fossil-free steel is made without the high carbon emissions associated with traditional blast furnace steelmaking.

Stefan Lundström, Business Unit President at Trelleborg Sealing Solutions in Kalmar, Sweden, highlighted the importance of this collaboration, stating, “With fossil-free steel in our components, we will take a leap forward in reducing our carbon footprint and that of the manufacturers that use our parts. This will strengthen our market-leading position.”

The demand for sustainable automotive components is on the rise, particularly within the EV market, where materials account for a significant portion of total CO2 emissions. By incorporating SSAB’s steel, Trelleborg aims to support car manufacturers in meeting these evolving sustainability expectations.

Olavi Huhtala, Head of SSAB Europe, expressed enthusiasm for the collaboration, saying, “We are happy to welcome Trelleborg Sealing Solutions as a fossil-free partner. Together, we will support the automotive industry in delivering the key parts that both producers and consumers are demanding.”

SSAB has pioneered two types of steel with minimal fossil carbon dioxide emissions: SSAB Zero and SSAB Fossil-free steel. The company has been at the forefront of innovation with HYBRIT technology, a groundbreaking method that uses hydrogen to produce iron, virtually eliminating CO2 emissions from steel production.