MAN Truck & Bus has partnered with Replique’s 3D printing platform to transform its spare parts manufacturing process. Leveraging additive manufacturing, MAN aims to produce critical components on-demand, locally, and without the need for physical inventory.

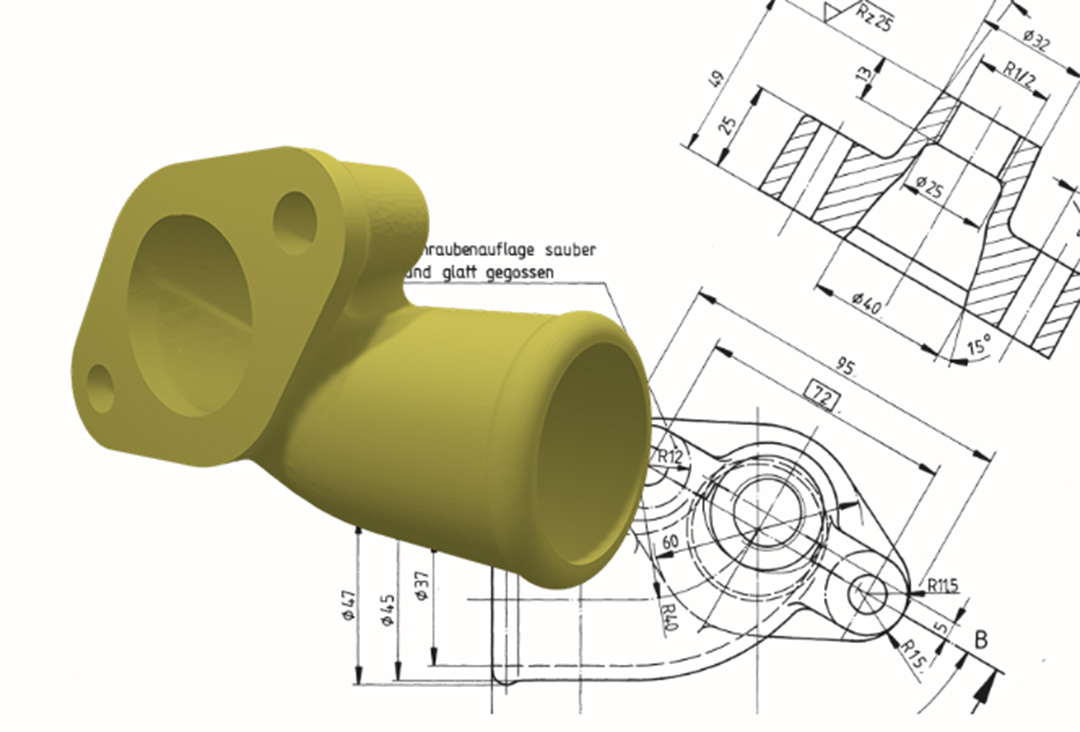

Facing challenges in spare parts management, MAN recently needed 10 bronze manifolds for a marine engine’s cooling water supply that were no longer in stock, and the casting mold was unavailable. Instead of traditional procurement methods, MAN turned to Replique for an alternative solution. With a 3D model and manufacturing drawing, Replique reproduced the manifolds using Selective Laser Melting (SLM) with the material m4p™ Brz10.

The collaboration with Replique resulted in the delivery of ready-to-install parts within approximately 7 weeks, surpassing the technical properties of the original material. Tensile tests conducted by MAN’s Central Material Technology department confirmed the superior quality of the 3D printed manifolds. The success led MAN to place an additional order for 10 units.

The digital availability of production information allows MAN to reorder the 3D printed manifolds at any time with consistent quality, eliminating fixed costs for molds, models, and storage. Thomas Hauck, Spare Parts Logistics MAN, praises the seamless collaboration with Replique and expresses ongoing plans for more 3D printing projects.