Drydocks World, a subsidiary of DP World, has converted two Liquefied Natural Gas (LNG) vessels to enhance production off the coast of the Republic of Congo.

In collaboration with Exmar, an Antwerp-based company, and Italian energy firm Eni, Drydocks World deployed the Tango Floating Liquefied Natural Gas (FLNG) and Excalibur Floating Storage Unit (FSU) vessels, marking a significant milestone in the Eni Congo LNG project.

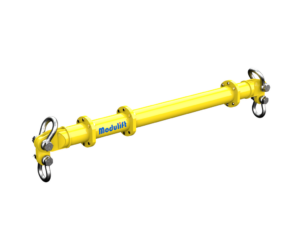

This groundbreaking project joined the two vessels using a ‘spread mooring’ system, a design and patent by Exmar. These combined assets work together to gather, liquefy, store, and offload LNG from Eni’s Marine XII block, located off the coast of Pointe Noire in the Republic of the Congo.

The conversion, including the addition of 12 steel mooring foundation structures totaling over 4,000 tonnes of steel, was completed by Drydocks World in just five months, with an impressive zero Lost Time Incidents (LTI) record. The project timeline was significantly reduced by pre-rigging the offshore mooring chains at Drydocks World’s Mina Rashid shipyard, a task typically done offshore but successfully accomplished by Drydocks World’s experienced sailors and marine riggers.

Drydocks World CEO, Capt. Rado Antolovic, PhD, expressed, “This high-profile project, conducted to the highest industry standards, in collaboration with our long-standing customers, Exmar and Eni, reaffirms our dedication to excellence and innovation in the maritime industry. Our committed team delivered a fast-tracked project tailored to our clients’ needs, maintaining exceptional quality throughout. We have a robust, solutions-oriented approach to provide sustainable solutions that support cleaner energy use in the maritime and energy sectors.”