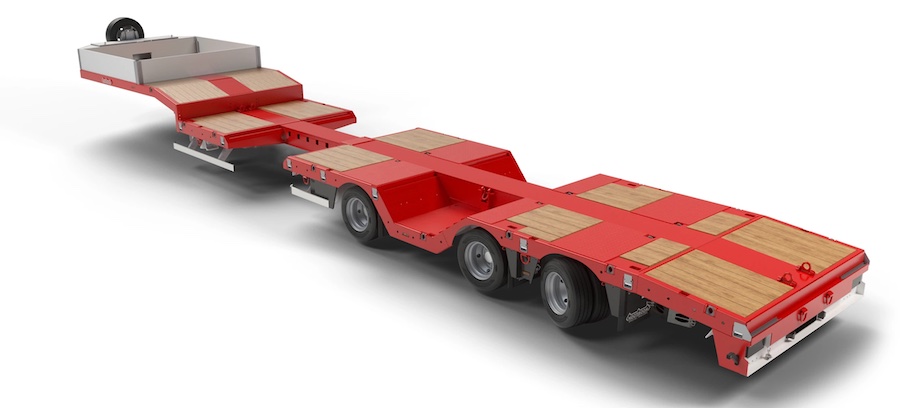

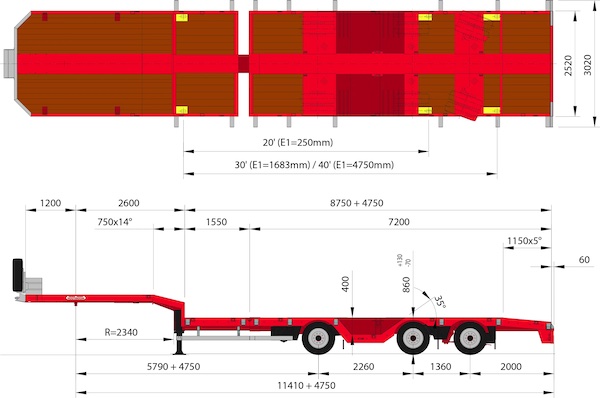

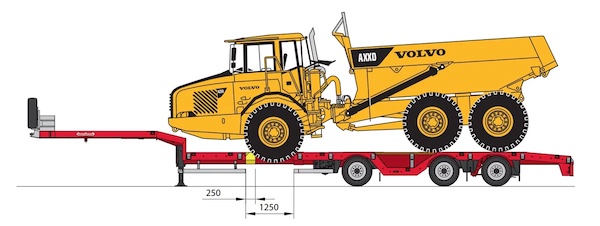

Nooteboom has expanded its SMART programme and introduced the new OSDS-48-03V(EBW) extendible lightweight semi low loader with wheel wells. This 3-axle semi low loader with self-tracking axle has a payload of up to 39 tonnes at 80 km/h. By applying a new concept of this semi low loader with 4750 mm extendable loading floor, a low deadweight of only 8.700 kg has been achieved. From now on, due to the deep wheel wells, also larger types of wheel loaders and articulated dump trucks up to 39 tonnes can be transported with this semi low loader, where previously this was only possible with a low loader. In addition, this OSDS-48-03V(EBW) is multifunctional, such as for the transport of divisible loads, containers and tracked construction machines. The short axle distance between the 1st and 2nd axle of only 2260 mm contributes to optimal manoeuvrability.

Complete specification

The quality is further reflected in the use of only top-quality A-brand components, as e.g. Jost landing legs, SAF axles, Hella lighting, Goodyear tyres and Wabco braking system. The semi low loader has complete standard equipment, including sliding outrigger consoles in the loading area, and can be optimised as required with the available options. Available options include a lift axle, removable intermediate tables, toolbox on the gooseneck, ferry rings, aluminum boards, ramps, storage trays and toolboxes under the loading floor.

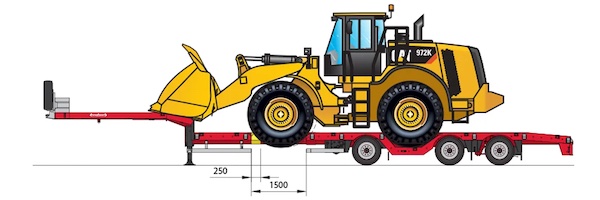

The asymmetric shape of the wheel wells makes it easier to unload wheeled loaders from the wheel wells, for example. The special inclination angle of only 35 degrees of the 400 mm deep wheel well facilitates exit from a standstill. In addition, these easy access wheel wells are equipped with steel cross ribs that provide maximum grip when driving in and out. The position of the wheel wells also provides optimal weight distribution between the gooseneck and the axle bogie. The wheel well dimensions are suitable for all common brands and types of wheel loader with different tyre diameters, axle distances and weights. For example a CAT 980K, a Doosan DL500, a Liebherr L586, a Volvo L220G, a Hitachi ZW370 or a Komatsu A500-6.

Variable wheel wells

The front wheel well is created by extending the loading floor. Using the optional sliding bolster with chamfered edges, the required space can be adapted to the tyre size and wheelbase of the wheel loader or dumper to be transported.

Easier loading and unloading

The long 1150 mm rear beaver with high ground clearance makes loading and unloading machines easier. For the loading and unloading of construction machines, the customer has a wide choice of ramps, ranging from 2.4-metre long aluminum ramps to automatically hydraulic folding 5-metre long ramps. For extra-wide machines, the hydraulic ramps and the standard sliding outrigger consoles can be extended to over 3 metres. In the case of aluminum ramps, they can be hooked up to a width of more than 3 metres. Smaller machines can also be driven onto the gooseneck using the special hook on ramps.

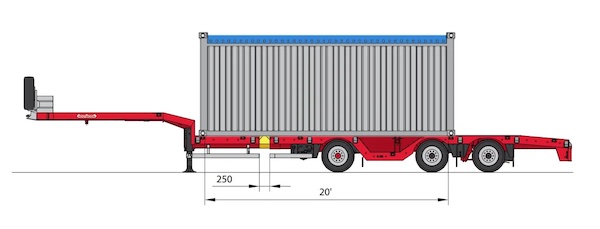

The semi low loader is not only limited to the transport of wheel loaders and dumpers, but also divisible loads, containers and tracked construction machines. If necessary, the wheel wells can easily be closed, creating a completely flat loading floor. For this purpose, removable galvanised supports with integrated sliding width enlargers and hardwood floor boards are available. As an option, the wheel wells can also be completely filled with hardwood parts. The semi low loader is equipped as standard with 3 pairs of holes for intermediate locks, so that 20′, 30′ and 40′ containers can also be transported.

Load securing

To secure the load, the semi-trailer is equipped with various TÜV-certified lashing eyes. They comply with international standards, allowing the load to be optimally secured in all directions. The gooseneck, for instance, is equipped with 5000 daN TÜV lashing eyes, and the load floor has no fewer than 22 pieces of 8,000 daN TÜV lashing eyes spread over the side raves and the centre beam of the trailer. In addition to these lashing eyes, lashing holes have been provided in the side raves for the attachment of lashing straps. Furthermore, the semi-trailer has optional all-round rope hooks under the side raves. As an option, this can be further enhanced with extra-strong 13,400 daN TÜV-certified lashing rings at the front and rear of the loading surface. Every conceivable load can be optimally secured on the OSDS-48-03V(EBW) with the highest safety standards.