De Beers has turned to ALE to ensure the removal and replacement of two engines on its Debmar Pacific mining vessel. Since 2002 diamond operations in Namibia have taken place in larger volume offshore than onshore, so its very important that mining vessel availability remains high.

Prior to the lift operation ALE installed two custom-designed gantries on either side of the vessel, parallel with the floor of its engine rooms. These gantries were enlarged at the client’s request, in order to provide better access to the engines.

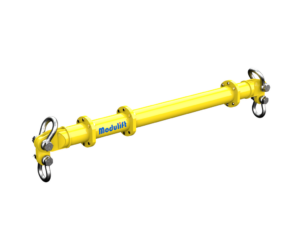

One by one, each engine was then jacked-up to a height of approximately 1m, using four 60t jacks. A medium skid track measuring 25m was then laid, from a position underneath the engine to the custom-designed gantry at the vessel’s exterior.

Each 38t GE engine was then skidded the length of this track, where it was uplifted using a 400t crawler crane and set down in a nearby storage area. This procedure was completed in reverse in order to install both 80t Wartsilla engines.

As time in port at Cape Town was limited to just a few weeks, several other similar procedures were taking place at the same time, meaning this work had to take place under strict space limitations.