For the first time, wind turbine manufacturer Enercon has deployed its new Scheuerle BladeLifter for rotor blade transport. The innovative solution, recently delivered by TII Scheuerle, was used during the construction of the Olsbrücken wind farm in Rhineland-Palatinate, Germany, where it proved its effectiveness under challenging conditions.

At the site, two new Enercon E-138 EP3 turbines with a hub height of 160 metres are being installed. Together with existing units, the wind farm will deliver a total capacity of 8.52 megawatts to the grid. Operated by juwi Beteiligungs GmbH & Co. Natur-Power 4 KG, the new turbines are scheduled for commissioning in early November.

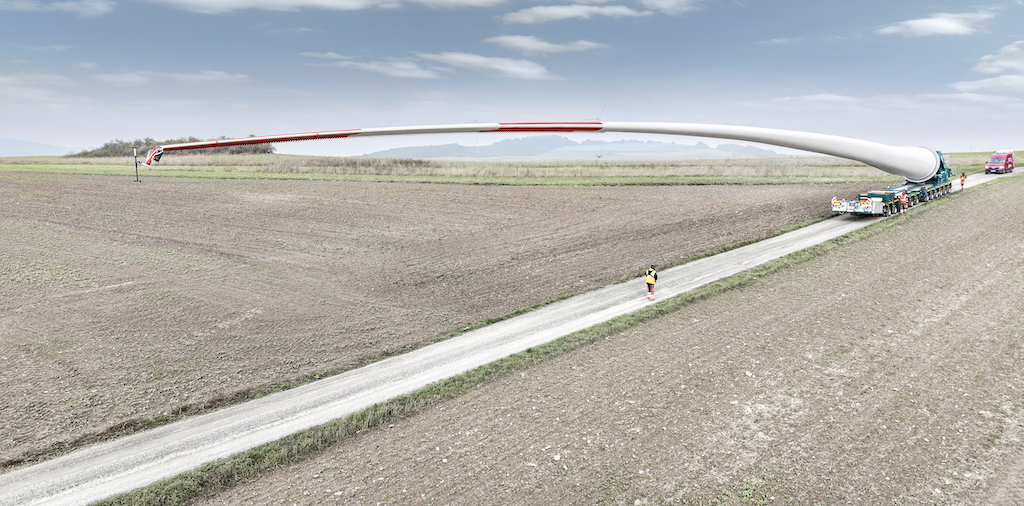

The key challenge was transporting rotor blades approximately 68 metres long through narrow village streets, railway crossings, and winding rural roads. Using the Scheuerle BladeLifter G4 for the first time, Enercon successfully completed the task. The system allows hydraulic lifting and tilting of blades by up to 60 degrees, ensuring safe and efficient transport even on complex routes.

“The BladeLifter G4 opens up new possibilities for us in rotor blade logistics,” said Björn Feddermann, Global Logistics Project Manager at Enercon. “It provides flexibility and reliability on demanding routes, and both the equipment and the crew performed excellently.”

Following the successful debut in Olsbrücken, Enercon plans to use the BladeLifter G4 again at the Bingen wind farm near Sigmaringen on Lake Constance—further demonstrating how advanced heavy-duty technology supports the growth of renewable energy through improved efficiency and reduced infrastructure impact.