DP World has taken a groundbreaking leap in employee safety by introducing the world’s first remote pinning station at its Southampton hub, significantly enhancing safety and efficiency in a crucial aspect of port operations.

The term ‘pinning’ refers to the manual placement of twistlocks into the corner casting of containers to secure them during sea voyages. For the past half-century, this process has occurred on the quayside, right beneath container-bearing cranes, posing inherent risks due to the close proximity of heavy machinery and personnel.

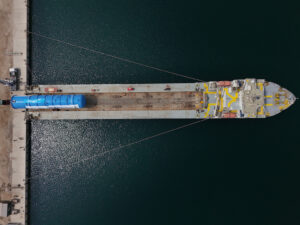

The innovative remote pinning station at DP World Southampton represents an unprecedented development in straddle carrier ports worldwide. Spanning the size of two football fields and positioned 150 yards away from the quay, it provides an extra layer of protection for workers. The remote system allows the straddle carriers, responsible for moving containers handled by quay cranes, to transport each container from the berth to the pinning station.

Steve McCrindle, Port Operations Director at DP World, expressed his satisfaction, stating, “We are delighted that our remote pinning station will make Southampton the first port of its kind to operate this way anywhere in the world. Along with providing the safest possible environment for our vital staff, we are confident it will also lead to improved productivity, maintaining Southampton’s status as Britain’s most productive port. This will offer customers a faster service than any of our competitors and drive our end-to-end logistics offering.”

DP World aims to move 35 containers per hour. Already, the Southampton hub achieved two consecutive records for container handling earlier this year. In April, the team completed 9,416 container moves in just 88 hours from the Hapag-Lloyd AG vessel Al Nefud. This achievement was made possible by a new operating model that allowed workers to focus more cranes on the vessel while simultaneously serving other customers.