Key nuclear components, including the reactor pressure vessel (RPV) and steam generators, have been successfully installed at EDF’s Hinkley Point C project in Somerset, UK, following years of detailed engineering and site coordination.

With multiple contractors operating heavy equipment simultaneously, the operation required meticulous planning, strict safety controls, and constant communication to ensure installation was completed safely and on schedule. Space constraints inside and around the reactor building further increased complexity, demanding a highly specialised transport and lifting approach.

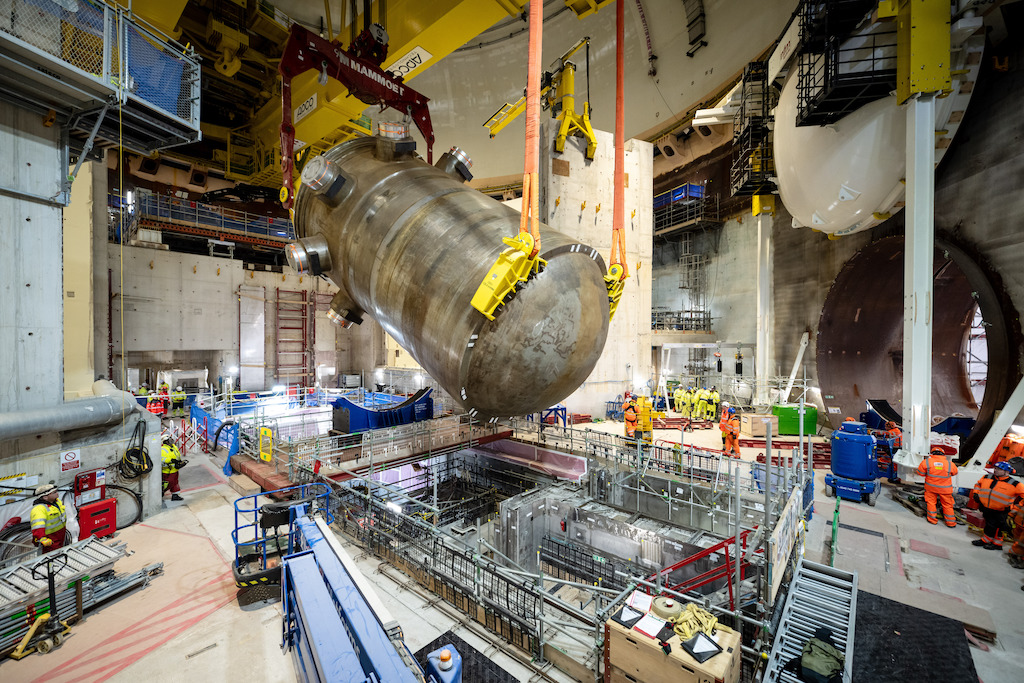

Framatome, the manufacturer of the RPV and steam generators, appointed Mammoet to handle the installation of the plant’s most sensitive components. Weighing up to 520 tonnes, these units form the “beating heart” of the nuclear plant and will enable each unit to generate enough electricity to supply around three million homes.

Crucially, Framatome required a solution that did not rely on existing on-site lifting equipment, ensuring greater operational flexibility and reducing dependency on other construction activities.

Mammoet developed a bespoke Outside Lifting System (OLS), combining winches and strand jacks to lift components directly from self-propelled modular transporters (SPMTs) and lower them onto a skid system for entry into the reactor building. Unlike conventional straight skid routes, a 30-degree curved path was engineered to match the building geometry, supported by a custom turntable allowing controlled rotation during transport.

Once inside, loads were lifted, rotated from horizontal to vertical, and lowered into final position using Temporary Lifting Devices (TLDs) integrated with the polar crane.

The grid-powered solution also reduced noise and carbon impact, improving overall site safety.