The National Composites Centre (NCC) is set to establish the UK’s first Large Structures Innovation Centre (LSIC), a major new facility that will enable industry to design, manufacture and test the next generation of large-scale composite structures at full industrial scale. The open-access centre aims to close a long-standing capability gap in the UK, providing companies working on large and complex components with advanced equipment, engineering expertise and the space required to accelerate innovation and product development.

Operated by the NCC, part of the High Value Manufacturing Catapult, the LSIC will build on more than 15 years of composite technology leadership. By integrating digital design, engineering support and real-world demonstration, the centre will help organisations progress technologies through every stage of the lifecycle, from early concept to end-of-life recycling and refurbishment. The ambition is to industrialise breakthrough concepts faster, strengthen UK supply chains and maintain national leadership in high-value manufacturing.

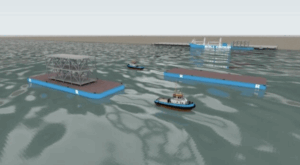

A central focus of the LSIC will be the offshore wind sector, where increasing turbine blade size is critical to delivering clean energy targets and lowering costs. The facility will give industry the ability to de-risk new automation methods, materials and structural designs offline from live factories while working at the full size and scale demanded by next-generation wind systems. This approach will bridge the gap between laboratory testing and commercial production, enabling faster validation and deployment of new blade technologies.

NCC Chief Executive Richard Oldfield said the LSIC will provide the infrastructure needed to turn “world-class research into industrial reality,” supporting both national energy goals and advanced manufacturing competitiveness. Early innovation projects are expected to begin in 2026, with a full launch planned for 2027. Further details on industry collaboration will be announced as development progresses.