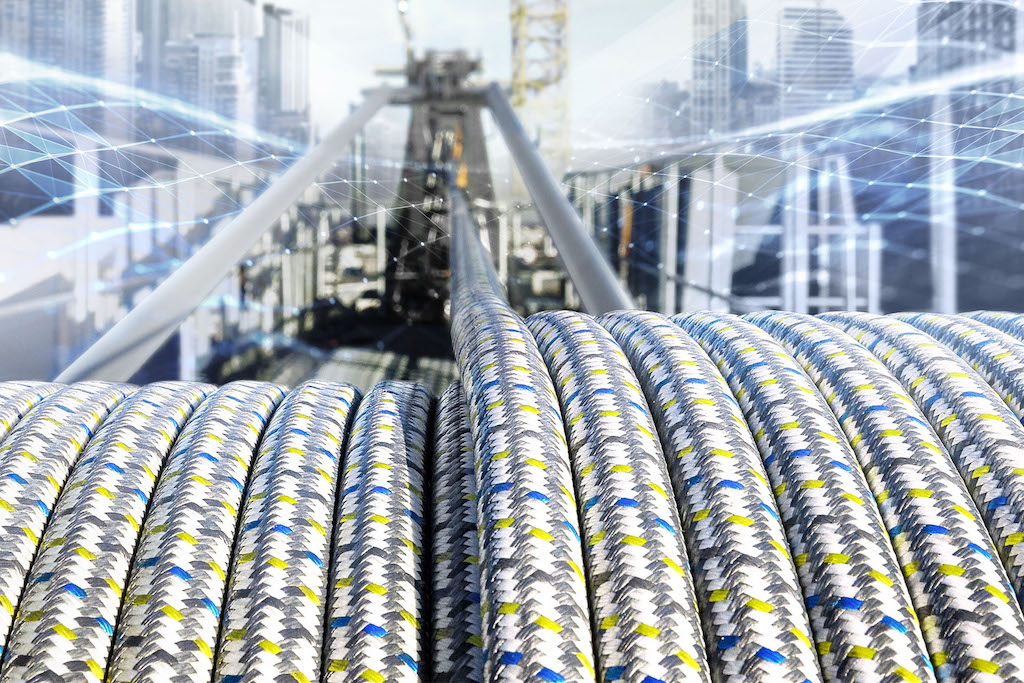

Liebherr’s Fibre technology continues its rapid rise worldwide, with more than 300 Fibre-equipped cranes now operating successfully on construction sites. Developed in close collaboration with partners and customers, the latest generation of the innovative hoist rope delivers greater efficiency, cost savings, and sustainability. Key advantages include on-site repairability, an extended service life of up to 14 years, and the option to convert between fibre and steel rope systems.

The newest updates mark a milestone: simplified rope-shortening and repair procedures now allow up to 85% of ropes to be repaired directly on site, significantly reducing downtime and replacement costs. Liebherr has also expanded its service offering with tailored on-site support and a “second life” programme for reconditioned ropes.

Contractors and rental companies across Europe are quickly embracing the technology. Ireland’s John Paul Construction has added Fibre cranes to its fleet after successful rental experiences, while Norway’s Utleiecompagniet AS has committed to purchasing only Fibre cranes going forward, citing higher lifting capacity, easier handling, no lubrication requirements, and longer service life. The Beutlhauser Group also highlights the major economic benefit of rapid on-site repairs, often completed within two hours, minimising operational interruptions and lowering long-term machine costs.

According to Liebherr specialists, the combination of repairability, reduced maintenance, cleaner operation, and improved safety has cut downtime risk to around two percent. Lower spare part prices and a more affordable extended warranty further strengthen the technology’s cost-effectiveness.