Mammoet has played a key role in constructing the first large-scale Carbon Capture and Utilisation (CCU) plant for Germany’s cement industry, located at Heidelberg Materials’ Lengfurt site. Commissioned by Linde Engineering, Mammoet provided the heavy lifting and installation expertise essential for the plant’s development within the confined space of the existing cement facility.

With early involvement in the project, Mammoet conducted a detailed feasibility study a year in advance. Leveraging its proprietary Move3D platform and a 3D model of the site, the team visualized complex workflows and spatial constraints. This enabled precise planning, reduced risks, and improved coordination across multiple contractors.

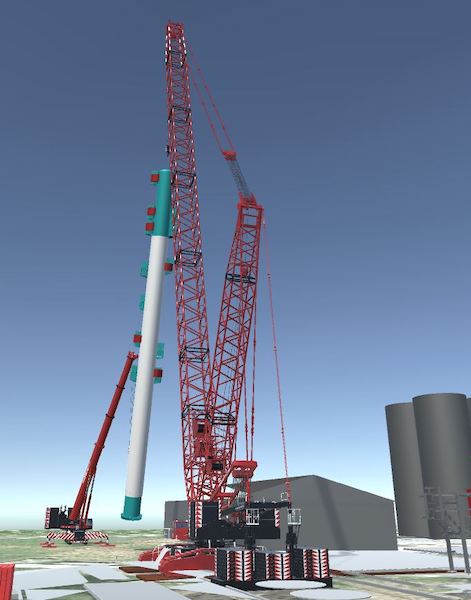

A 750-ton crawler crane was selected as the optimal lifting solution. It offered the flexibility to safely maneuver heavy components in tight quarters while minimizing ground impact. The most challenging lift involved a 100-ton, 55-meter-long absorber column, which was swung 180 degrees and carefully positioned behind a building before being secured in place.

Subsequent lifts included a 67-ton stripper column, four 72-ton tanks, and a 178-ton heat exchanger. By adapting the crane’s configuration shortly before execution, Mammoet also facilitated parallel construction of the steel structure, saving time and costs.

The CCU plant is part of the Cap2U joint venture between Heidelberg Materials and Linde, aiming to capture and liquefy CO₂ emissions. Mammoet’s early planning, 3D engineering, and on-site execution ensured a smooth, efficient build that supports the cement sector’s path toward decarbonization.