Alimak, one of the global leaders in vertical access solutions, has unveiled three products that are set to redefine the landscape of the construction industry. As construction projects evolve to meet modern demands for safety, sustainability, and operational efficiency, Alimak’s innovative offerings—the Scando 650a 40-46 S model, the STS 300 Scaffold Transportation System, and the Vectio 350 – represent a leap forward in construction hoisting, scaffolding, and material transportation.

The Alimak Scando 650a 40-46 S model marks a significant advancement in the design of construction hoists. Building upon the success of the Scando 650, which has been a fixture on construction sites since its introduction in 2004, this upgraded model incorporates new technology, focusing on performance, energy efficiency, and user-friendly features. The Scando 650a is designed to support a range of modern construction needs, offering increased payload capacity, improved operational control, and sustainability.

With a substantial 800 kg increase in payload capacity, the new Scando 650a boasts 4,000 kg capacity while maintaining the same car size. Despite this boost in performance, the model consumes 22% less energy than its predecessor, thanks to its utilization of lightweight materials and energy-efficient motors. The hoist’s height has also been extended to 400 meters, catering to high-rise construction projects. The model is engineered to accommodate existing accessories, ensuring compatibility with previous models and offering a seamless integration into ongoing operations.

A highlight of the Scando 650a is its advanced Human-Machine Interface (HMI), which features a high-resolution touchscreen. This innovative control system provides real-time updates on hoist status, enhancing user interaction and control. Furthermore, the hoist’s three new driving modes—Eco, Optimized Speed, and Reduced Speed—allow construction teams to tailor the operation to the specific needs of the job, optimizing energy consumption, noise levels, and logistics on the job site.

Environmental sustainability is central to the design of the Scando 650a. With 97.5% recyclable materials and energy-efficient production processes, the model is crafted to minimize its carbon footprint while delivering superior performance in challenging construction environments.

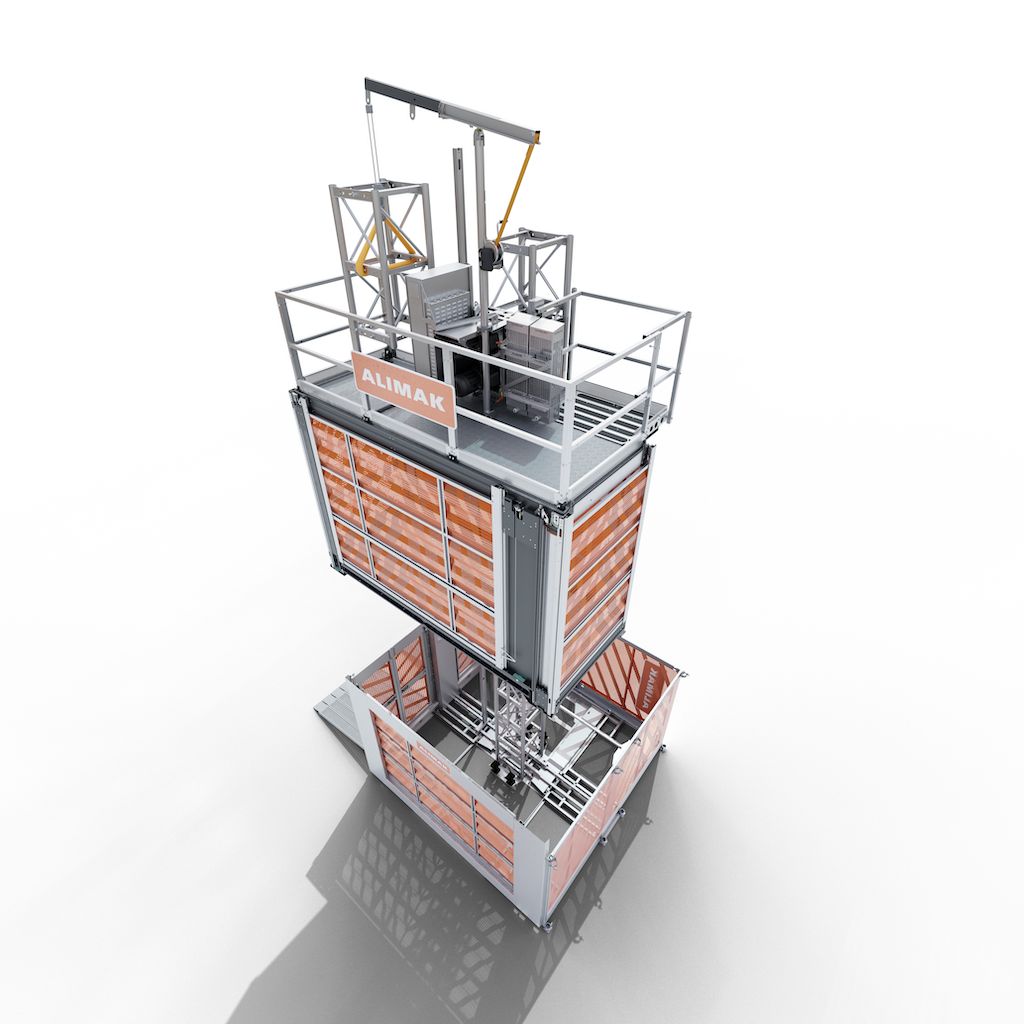

STS 300 Scaffold Transportation System

In addition to vertical access, Alimak has introduced the STS 300 Scaffold Transportation System, a solution designed to streamline scaffolding operations on construction sites. The STS 300 aims to enhance efficiency by facilitating the vertical and horizontal transport of scaffolding materials, reducing labor costs and improving productivity.

The STS 300 is capable of installing up to 300 square meters of scaffolding per day with just two operators, a significant improvement over traditional methods. With a payload capacity of 300 kg and a transport speed of 17 meters per minute, the STS 300 accelerates material handling, ensuring that projects stay on schedule and within budget. This system’s ergonomic design reduces the need for manual handling, with a swivel loading mechanism and ground-level loading capabilities that prioritize operator safety.

Safety and operational efficiency are further enhanced with features such as minimal crew requirements and a swivel box that allows for safer material transfer. These innovations enable teams to complete scaffolding installations with greater speed and precision, all while reducing the risk of injury on-site.

Vectio 350 Transport Platform

Rounding out Alimak’s new product offerings is the Vectio 350 transport platform, a versatile and compact solution designed specifically for smaller construction sites. With a dual-function design, the Vectio 350 can be used both as a transport platform and as a material hoist, providing flexibility for a wide range of tasks.

The Vectio 350 offers payload capacities ranging from 500 kg to 2,000 kg, with a maximum speed of 24 meters per minute. The platform’s intelligent driving mode automatically switches between transport and hoist modes, optimizing performance based on the specific requirements of the task at hand. This functionality enhances operational efficiency while reducing energy consumption and wear on components.

Safety remains a priority with the Vectio 350, which is equipped with overload protection, a Falling Object Protection System (FOPS), and improved ergonomics for easier installation and maintenance. The platform’s integration with Alimak’s My Alimak portal allows operators to monitor real-time performance, receive predictive maintenance alerts, and access operational data, all contributing to increased uptime and safety.

Additionally, the Vectio 350 incorporates AliSoft technology, a software-controlled starter that smooths the platform’s operation and reduces energy consumption. This feature ensures a reliable, energy-efficient solution for vertical access, making the Vectio 350 an ideal choice for projects where space and energy efficiency are paramount.

Alimak’s new product lineup will be available for order in mid-2025, with the STS 300 and Vectio 350 scheduled for release at bauma 2025.