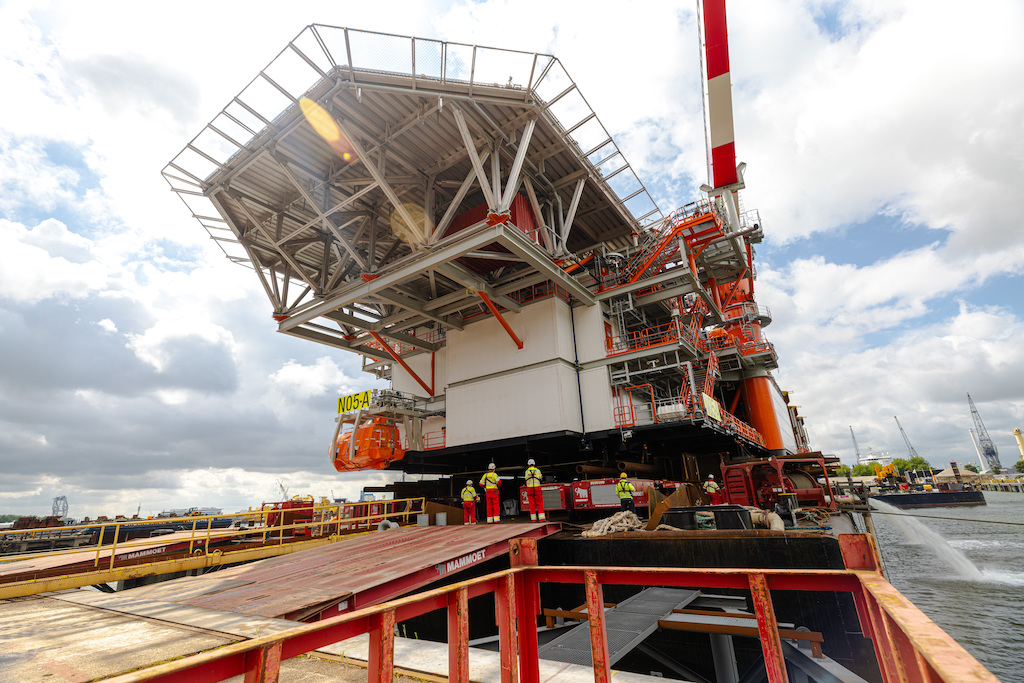

The N05-A platform, the first offshore gas platform in the Dutch North Sea to be powered entirely by wind energy, has successfully undergone an efficient load-out operation. The platform, part of the GEMS (‘Gateway to the Ems’) project, is powered by electricity from the 113.4 MW Riffgat offshore wind farm, reducing carbon emissions by over 85%.

Mammoet was contracted by HSM Offshore to handle the transport of the 3,050t topside and 3,150t jacket from HSM’s quayside fabrication facility in Schiedam, Rotterdam. The components were loaded onto a barge for offshore installation by platform owner ONE-Dyas.

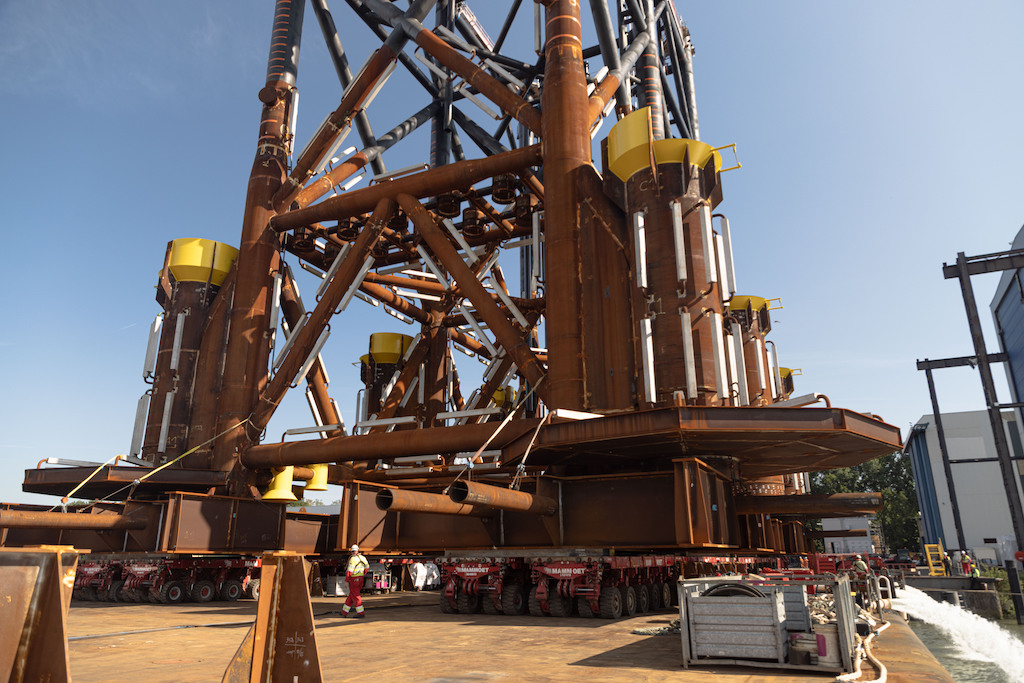

To optimize the schedule, Mammoet employed an innovative approach that allowed the jacket to be assembled close to its installation site, minimizing construction lead times. The assembly and weighing were executed using mobile cranes, conventional trailers, and Self-Propelled Modular Transporters (SPMTs). The jacket was fabricated in two sections, lifted by LTM 1650 and LTM 1450 cranes, and positioned using sheerlegs.

A key challenge was loading both the topside and jacket onto the same barge—an uncommon approach that required advanced engineering solutions. Conventional mooring was unfeasible due to load constraints, so a spud leg barge was deployed for vessel stabilization. The final load-out operation took just two days, utilizing four 32-axle-line SPMT trains.

Given shifting timelines, Mammoet also prepared a contingency load-in site at its Schiedam yard, ensuring project continuity for HSM Offshore. Though ultimately unnecessary, this proactive planning underscored Mammoet’s adaptability.

“Through strong collaboration and early involvement, we optimized assembly and reduced lead times,” said Mammoet Project Manager Sven Segeren. This project marks a milestone in offshore gas electrification and sustainable energy integration.