Concordia Damen has announced its involvement in the launch of the Rotra Futura, the first of two advanced Offshore Wind RoRo vessels designed for the transport of large wind turbine components. The launch took place at Jiangsu Zhenjiang Shipyard, with the vessel set for delivery to Amasus in 2025. The project is the result of a collaboration between Concordia Damen, Amasus, deugro Danmark, Siemens Gamesa, and DEKC Maritime.

The development of the Rotra Futura and its sister vessel, Rotra Horizon, was driven by a concrete partnership between Siemens Gamesa, Amasus, and Deugro Danmark, aiming to meet the growing needs of the offshore wind industry. Working alongside Concordia Damen and DEKC Maritime, the partners focused on creating a cost-effective, energy-efficient, and sustainable vessel type to support the expansion of offshore wind energy logistics.

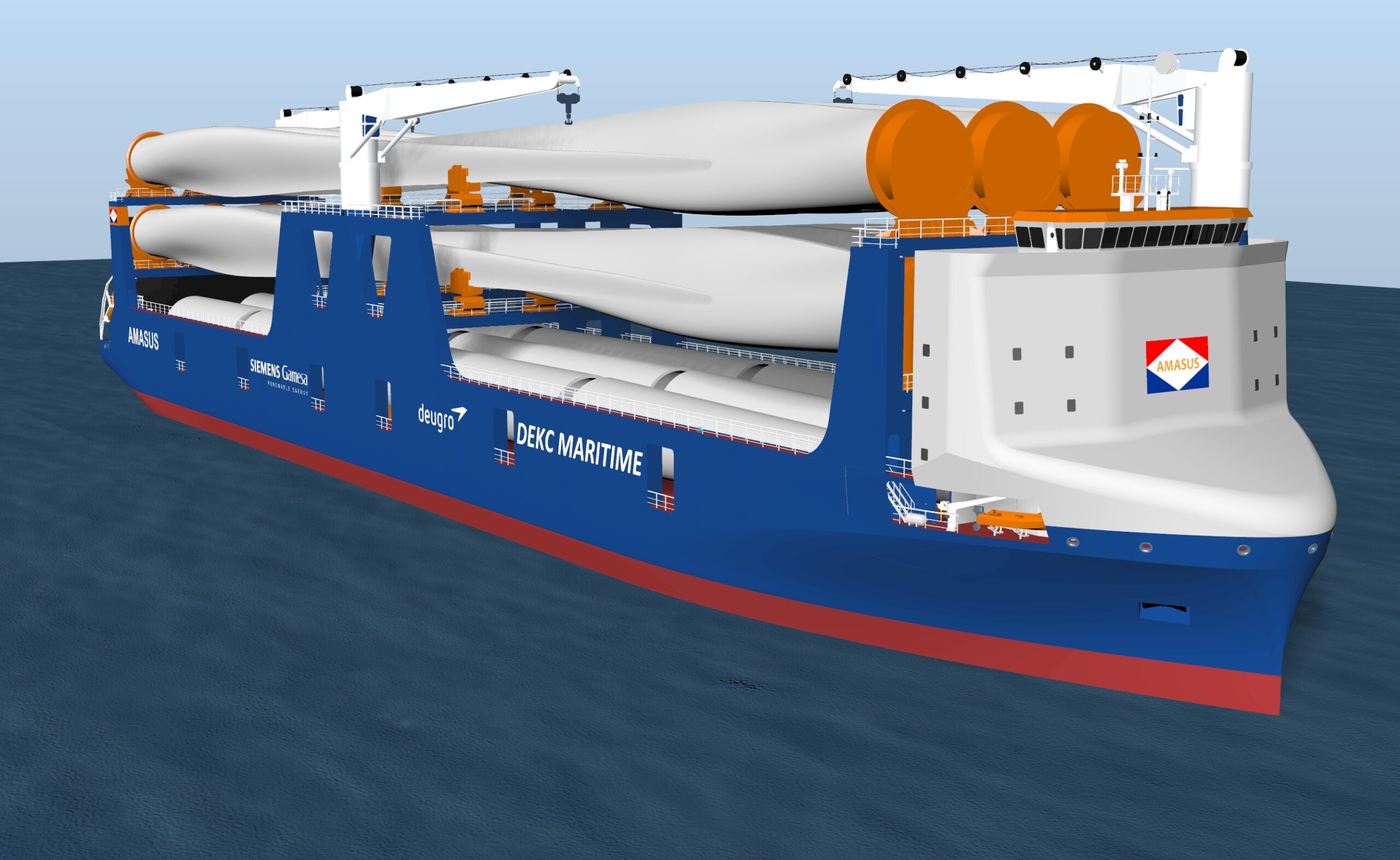

The vessels are designed to transport the increasingly large and heavy components of wind turbines, with an innovative RO/RO system (Roll-On/Roll-Off) and a custom ramp system that facilitates safe and efficient loading. With the ability to stow turbine blades in three tiers using Liebherr cranes, these vessels offer enhanced flexibility for cargo configurations.

Building on the successful Rotra Mare and Rotra Vente vessels, the new Rotra Futura and Rotra Horizon are equipped to handle the next generation of wind turbine components. The vessels feature a 167.6 x 26 meter hull, strategically placed wheelhouse and accommodation for optimal visibility, and design innovations to maximize cargo capacity.

Innovation in sustainable design has been central to this project. The vessels’ aerodynamic, hydro-optimized hulls and low-resistance coatings reduce fuel consumption, while the advanced Wärtsilä main engine cuts fuel use by 15% and CO₂ emissions. The hybrid propulsion system meets IMO Tier 3 standards, and an efficient waste heat recovery system further boosts energy efficiency.

“This project exemplifies our dedication to creating innovative, environmentally-friendly solutions,” said Chris Kornet, Managing Director of Concordia Damen. “By combining cutting-edge technology with sustainable practices, we are helping to drive the offshore wind industry forward.”