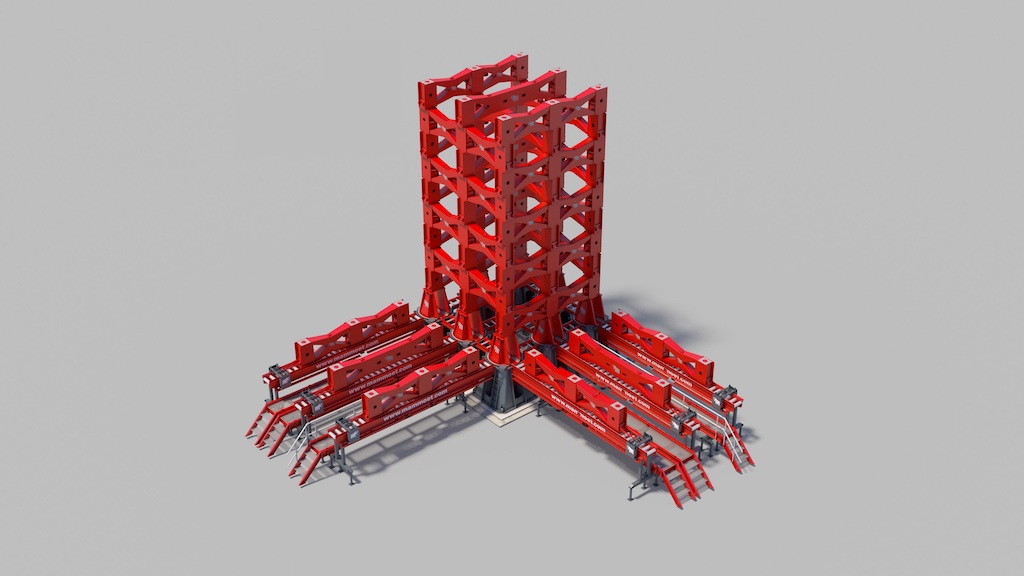

Mammoet has introduced the Mega Jack 10000, an advanced heavy lifting system designed to revolutionize the industry. With an upgraded lifting capacity of 10,400 tonnes per tower—double the capacity of its predecessor—the new system significantly reduces the need for custom steelwork and simplifies operations.

This enhanced capacity allows for fewer jacking towers, smaller foundations, and less steel to support structures during lifts. The new system also brings lifts closer to ground level, reducing the need for large cranes and improving safety and efficiency.

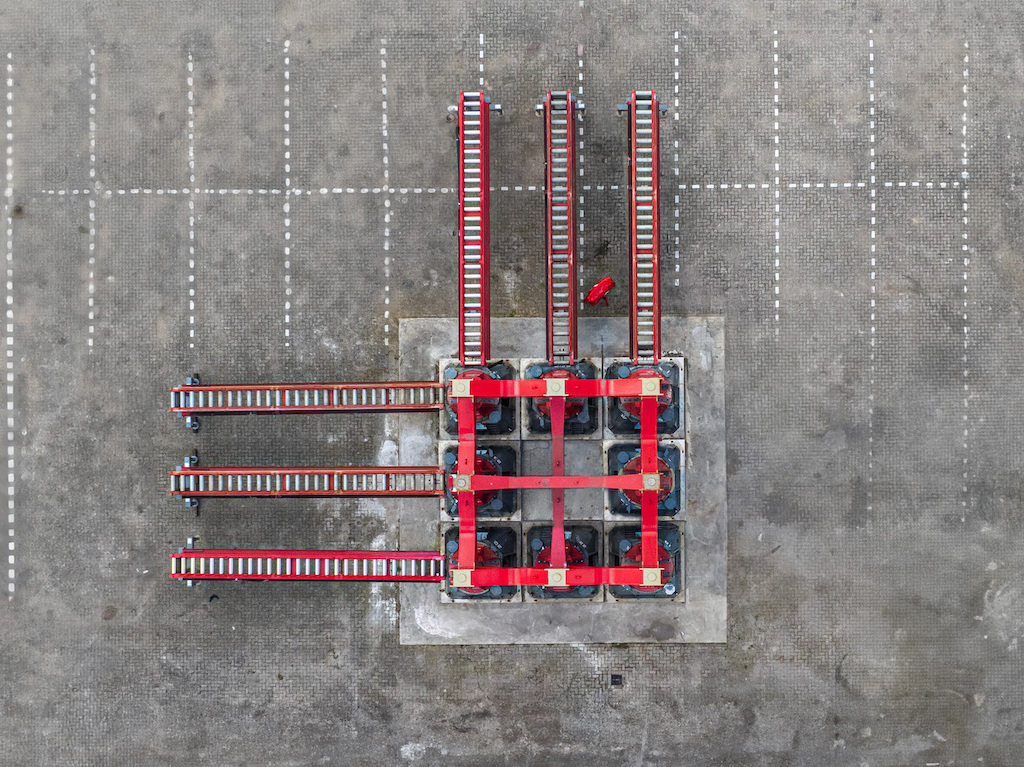

The Mega Jack 10000’s innovative design features a five-meter jacking beam with three connection points, distributing load across eight base units. This configuration minimizes the need for starter beams and reduces the size of supporting steel, streamlining project timelines and lowering costs.

Richard Verhoeff, Director of Sales for Global Special Devices at Mammoet, commented: “We saw loads increasing beyond the capacity of the Mega Jack 5200, and developed the Mega Jack 10000 to meet future demands. This new system sets a new standard in lifting technology, enhancing both safety and sustainability.”

The Mega Jack 10000 will be used in sectors like offshore oil and gas, renewable energy, and manufacturing, where loads can exceed 30,000 tonnes, making it ideal for large-scale projects that require efficient, cost-effective, and safer lifting solutions.