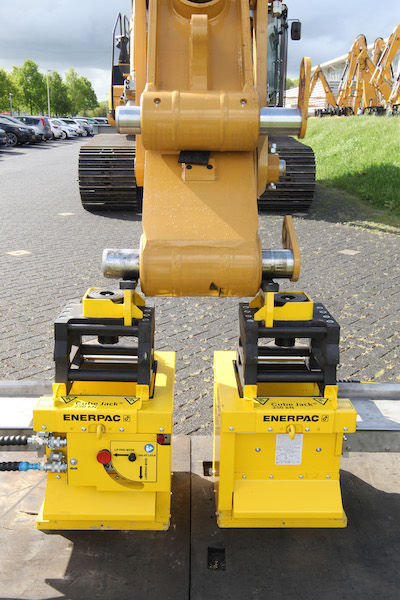

Enerpac, a specialist in hydraulic industrial tools, introduces an innovative lifting system for safer excavator maintenance. Utilizing the Enerpac SCJ-Series Cube Jacks, this system facilitates the lifting and secure holding of the entire cab, boom, and arm, allowing for the safe removal of the undercarriage.

Traditionally, maintenance of an excavator’s swing drive and bearings required separating the undercarriage from the upper body cab and arm, a process involving multiple service engineers and cumbersome jack stands. Enerpac’s cube jack lifting system offers a safer alternative, certified by CE, streamlining this procedure.

Consisting of two pairs of cube jacks, capable of lifting loads up to 25T per jack to a height of 2m, this system ensures coordinated hydraulic lifting. Positioned strategically under a lifting beam at the rear of the excavator and under the arm’s bucket lugs, the cube jacks are synchronized via hydraulic pumps, enabling precise lifting and lowering.

Developed in collaboration with a leading excavator maintenance company, this system automatically self-locks, allowing engineers to work securely under the raised cab without additional jack stands. Its safety features, secure load holding, precision lifting, and easy setup have garnered positive feedback from users and customers.

Enerpac’s cube jack technology, showcased in the SC-Series Cube Jacks, offers a proven solution for various industrial lifting applications. These jacks utilize a base lifting frame and lightweight steel cribbing blocks for stable, high-capacity lifting, presenting a safer and more efficient alternative to traditional climbing jacks with wooden cribbing.

Tested by Lloyds to 125% of the maximum working load, the incremental cube jack lifting system self-locks to support the load as cribbing blocks are added or removed manually. Once engaged, the mechanical lock allows for smooth retraction of the lift cylinder, facilitating easy adjustment during maintenance tasks.