Mammoet showcased its commitment to reducing carbon impact in civil projects with the successful installation of an 850-ton concrete tunnel section beneath railway lines in Belgium, all achieved emissions-free.

Partnering with STADSBADER CONTRACTORS, Mammoet utilized a combination of existing skidding equipment and innovative battery-powered technology to execute the project, ensuring minimal disruption.

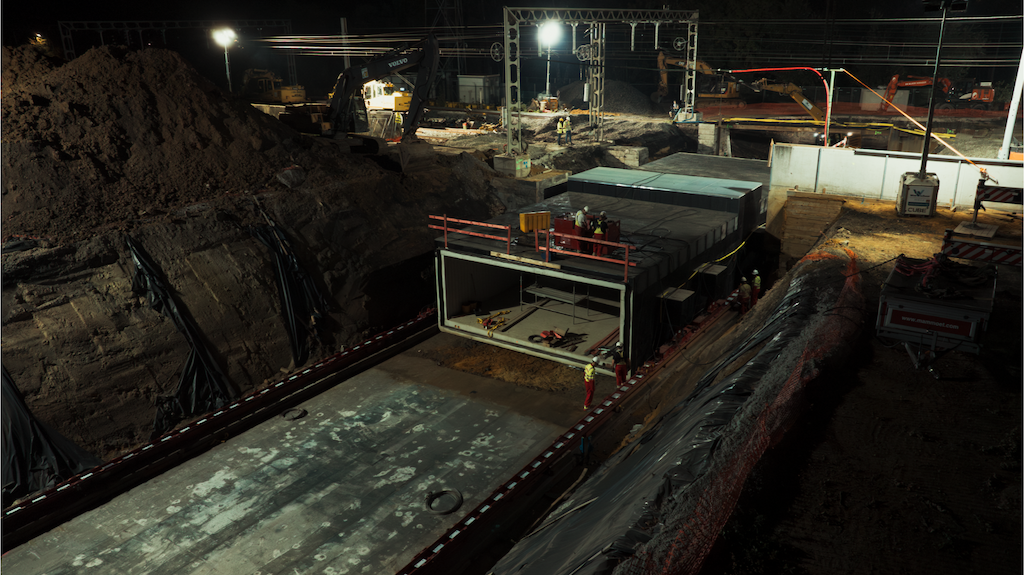

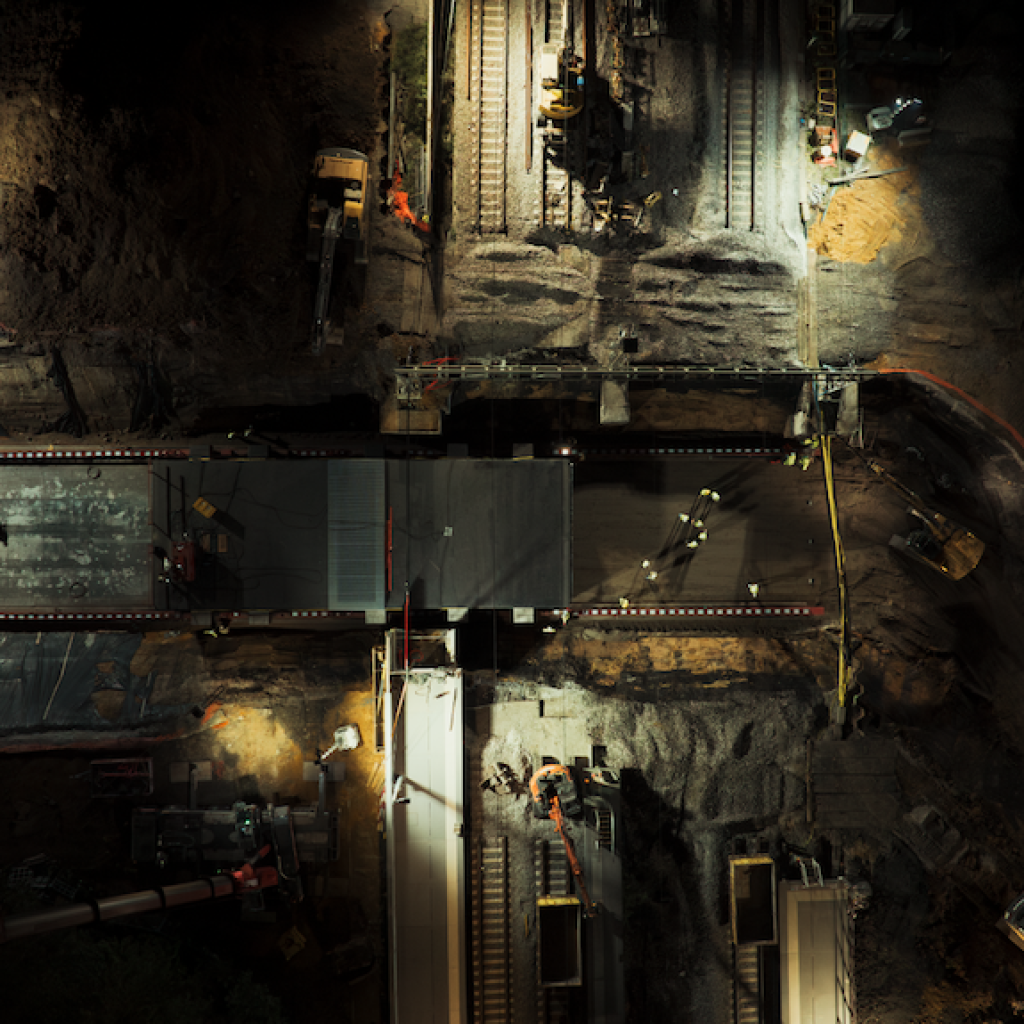

The operation, involving lifting and skidding the 25m x 8.5m tunnel section across 40 meters to its destination near Brussels, demanded precise planning and execution. Mammoet’s specialized tunnel adaptors and hydraulic jacks facilitated the process, powered by an electric powerpack with a recycled battery.

Feasibility tests, including smaller scale projects like transformer installations, preceded the Belgian operation. Despite its complexity, the skidding procedure was completed under an hour, exceeding estimated schedules by 2.5 hours.

The Mobile Power Unit, weighing 1,460kg with a 50kWh battery capacity, can be solar-charged, making it sustainable and adaptable even in remote locations.

This achievement not only highlights Mammoet’s leadership in safe and sustainable heavy lifting but also emphasizes positive outcomes such as reduced noise levels and environmental impact. Pascal Eeken, Manager Improvement and Innovation at Mammoet Europe, stressed the significance of innovative engineering in realizing zero-emission projects, setting a new standard for eco-friendly heavy lifting practices.

By pioneering the transition to zero-emission electricity in civil projects, Mammoet continues to lead the industry towards a more sustainable future, supporting environmentally-conscious development.