Mammoet has welcomed the arrival of its first electric Liebherr mobile crane, the LTC 1050-3.1E. This innovative crane features both an electric motor and a traditional drive system, providing the option to carry out crane movements using electricity. This contributes significantly to reducing carbon emissions and aligns with the demand for “zero emission” construction sites.

The LTC 1050-3.1E marks the inaugural electrically powered hydraulic crane in Mammoet’s extensive fleet. Peter van Oostrom, Director Global Projects and Assets at Mammoet, sheds light on their decision to opt for this 50-ton crane: “Cranes in the 50-ton range are ideal for testing innovative technologies, as they are constantly in operation for Mammoet. This allows us to introduce these new technologies to a broad customer base, testing their practicality for everyday industrial use.”

As a heavyweight in the crane and heavy lifting industry, Mammoet places a strong emphasis on sustainability and cutting-edge technologies. Van Oostrom affirms their commitment, saying, “We are dedicated to spearheading the industry’s adoption of groundbreaking technologies that reduce the environmental impact of heavy lifting projects.” To this end, Mammoet has developed various eco-friendly solutions, such as the world’s first electric modular self-propelled transporter and the SK electric crane series.

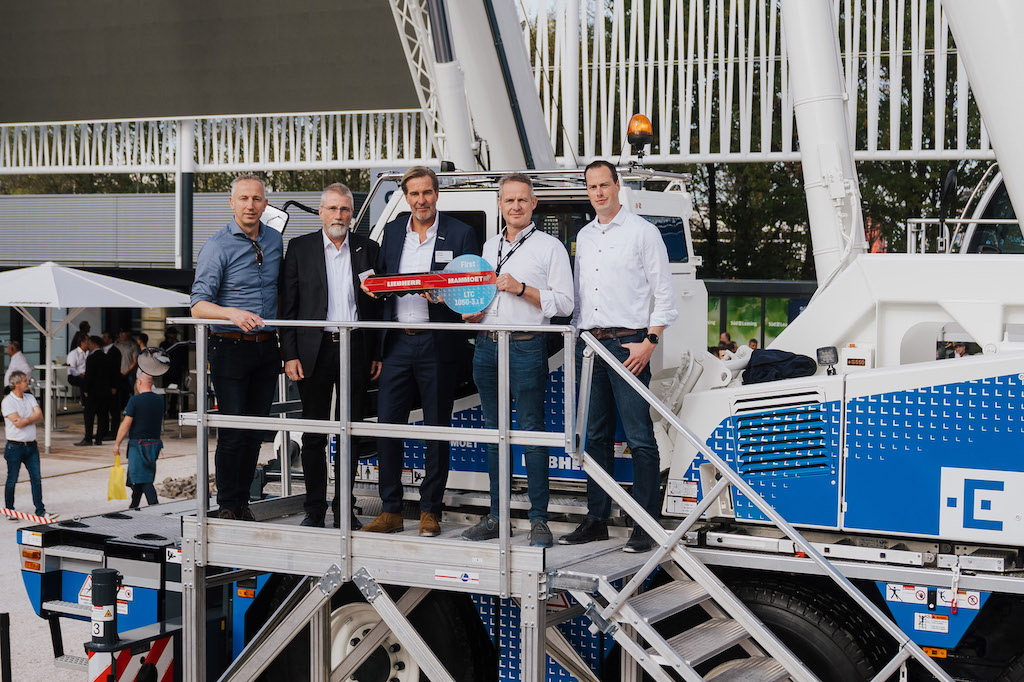

Contract officially signed at Bauma 2022: (F.l.t.r.) Peter van Oostrom (Mammoet), Dr. Ulrich Hamme (Liebherr-Werk Ehingen GmbH), Han Rekers (Liebherr-Nederland B.V.), Jan Kleijn (Mammoet), Hermen Kamp (Mammoet)

One key feature Mammoet highlights is the compactness of the LTC 1050-3.1, offering flexibility for projects in confined spaces, especially indoor environments where zero emissions and reduced noise during electric operation are crucial. Mammoet equipped the crane with Liebherr RemoteDrive for precise remote control in tight conditions.

The electric LTC 1050-3.1 offers a compelling blend of environmental friendliness, customer benefits, and efficiency. On the road, it is powered by a low-emission combustion engine meeting exhaust emission stage 5 standards, providing 243 kW (326 hp). This engine can be fueled with hydrogenated vegetable oil (HVO), reducing CO2 emissions by up to 90% compared to pure diesel.

During crane operations, operators can choose between the combustion engine and the electric motor based on the specific operating conditions. The newly developed electric motor offers 72 kW, delivering nearly the same performance as the 6-cylinder engine. The electric model includes the electric motor, a transfer case, and necessary control technology. This intelligent yet straightforward solution facilitates seamless transitions between diesel-hydraulic and electro-hydraulic drive. While full performance requires 125 amps of site power, practical operation is possible with 63 amps. Additionally, the crane can be operated using an external “battery pack,” like the Liebherr energy storage system Liduro Power Port (LPO), if the construction site lacks the necessary electrical infrastructure.