Renowned for their expertise in natural gas monetization, Wison, has announced their acquisition of five RL series cranes from Liebherr. This strategic investment is a pivotal component of their ongoing project, the Natural Gas Liquefaction Plant (FLNG), which has been under construction since the early months of 2023. Notably, this venture marks the company’s largest FLNG project to date, commissioned by the Italian energy firm, Eni. This colossal vessel, measuring an impressive 380 meters in length and 60 meters in width, will find its anchorage at a depth of 40 meters off the shores of the Republic of Congo.

Each crane within the RL series portfolio will play a pivotal role in supporting the FLNG unit’s maintenance and supply operations. Stefan Schneider, the Global Application Manager for General Purpose Offshore Cranes, expressed, “The fact that we’ve persuaded Wison to opt for the entire RL series stands as both a triumph and an impetus for Liebherr to continue tailoring their offshore portfolio to meet the market’s and customers’ requisites. The collaboration with our contract and service partners from Liebherr China Co. (LMS China) played a particularly pivotal role in finalizing this agreement. They will be integral in supporting the construction of the FLNG, with a field office taking charge post-commissioning.”

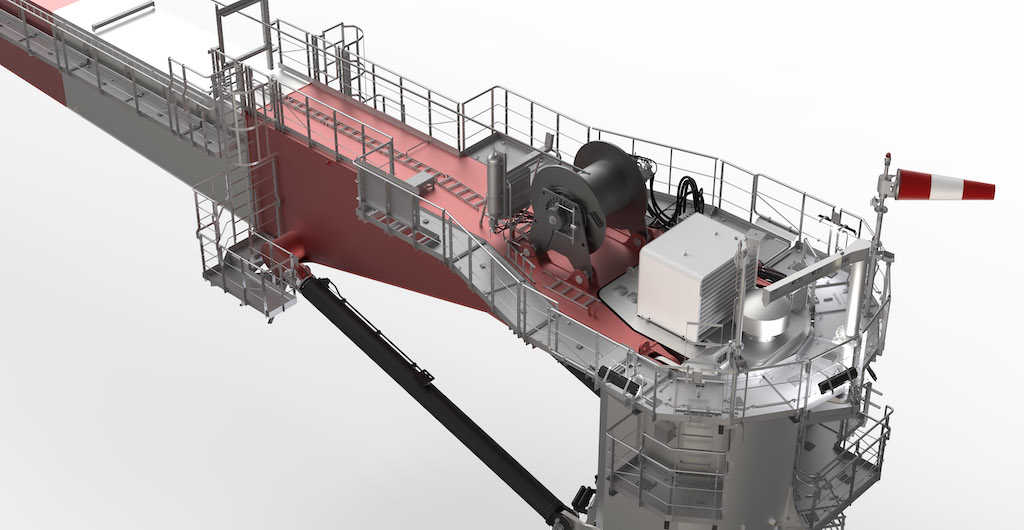

Optimal design embodies the hallmark of reliable and adaptable crane control. The compact and weight-optimized crane architecture within the Liebherr RL series empowers it to be deployed with utmost efficiency, even within space-constrained environments, all thanks to a meticulously planned design approach. This is evident through an optimized overall height, a minimal tail radius, and the absence of a machinery house. These cranes also bestow numerous benefits upon their operators. The overhauled 7-cubic-meter cabin boasts an ergonomic design, facilitating fatigue-free work. Modern equipment, coupled with superior visibility, a novel driver’s seat, and a revamped operating concept featuring updated controls and air conditioning, ensures the safe operation of these cranes. Mr. Zhang Shouyue, Deputy General Manager of Project Management Office at Wison, emphasized, “Equipping the FLNG with the RL series delivers comprehensive value, with the highest safety standards and state-of-the-art working conditions enhancing productivity. For us, partnering with Liebherr means having a global crane manufacturer at our side, whose expertise sets global benchmarks.”

The newly established floating plant can accommodate over 180,000 cubic meters of liquefied natural gas and 45,000 cubic meters of liquefied petroleum gas. The cranes situated on the platform are integrated into a comprehensive service infrastructure. Yang Dong of Liebherr China Co. emphasized, “The modular design concept of the primary components within the Liebherr RL series is indeed a remarkable aspect, with enhanced component interchangeability.”

The RL crane series also boasts a range of additional features. This includes the pioneering cabinet located inside the slewing column, housing the world’s first explosion-protected Ex d cabinet, designed to safely dissipate explosion pressure. This innovation, named “EXpressure,” was developed in collaboration with Liebherr partner R. Stahl AG. Furthermore, the RL series offers LiMain, a fully digital, remote-controlled, and semi-automated maintenance system, which, with its modular approach and customizable maintenance packages, allows for future maintenance that is independent of constraints related to time, location, or resources.