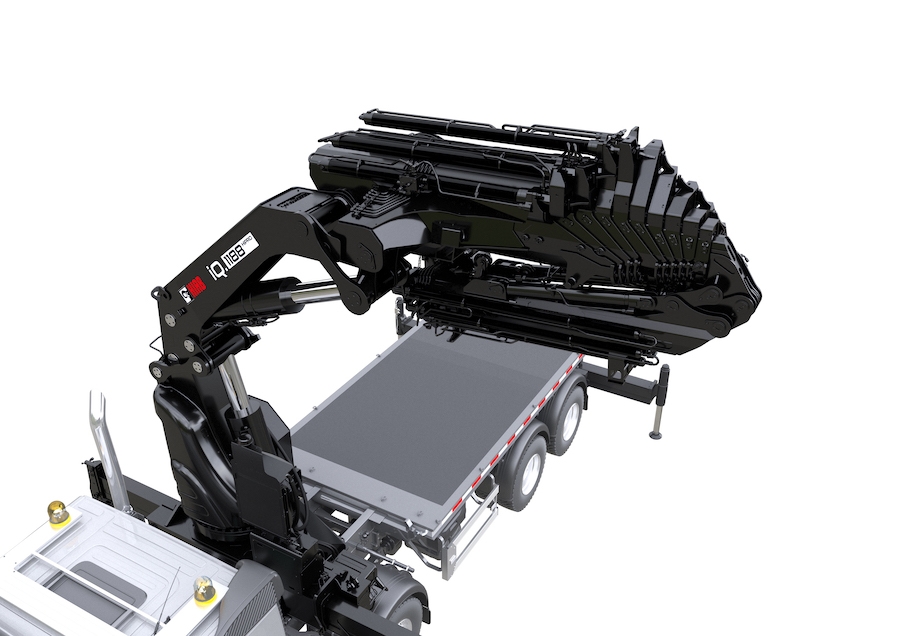

Hiab has launched the 110 tonne metre ™ super heavy loader crane HIAB iQ.1188 HiPro with the company’s new control system to deliver productivity and safety benefits. The iQ range is HIAB’s new generation of loader cranes based on the new control system SPACEevo combined with the CombiDrive 4 remote control that is used for the first time on the HIAB iQ.1188 HiPro.

The HIAB iQ.1188 HiPro is the largest HIAB crane to date with a long reach and great lifting capacity, but still lightweight in a compact package. It delivers the performance of a 110tm loader crane but is similar in size to a 90tm range model. This means it can be installed easily on 4 axle vehicles and still leaves room for payload, as well as reducing costs and fuel consumption. The performance to weight ratio is achieved by the new V12-Power boom profiles.

“Our customers want big cranes that are suited for a great variety of tasks in a smaller crane package to increase flexibility, reduce operating costs and improve fuel efficiency. We are proud to have launched our biggest HIAB crane to date with some amazing new technological features to deliver unrivalled performance and safety features,” says Marcel Boxem, Director, Product Management, Loader Cranes Heavy & Super Heavy, Hiab.

He continues: “The HIAB iQ.1188 HiPro is the first in the iQ. range that will set a new standard for precise manoeuvres and high speeds, and personalised settings to improve productivity. At the same time, the new features we are introducing are also making crane operation safer than ever for the operator and the surroundings.”

The new SPACEevo control system allows the crane to be operated precisely even at high speeds. It is built using an open technological platform that enables continuous updates. The crane is controlled by the new remote control CombiDrive 4 that provides more information, with bigger colour screens, haptic feedback (vibrations) and increased battery life. It is possible for the operator to personalise settings like speed and crane reaction. It features the new Confirm View that increases safety by identifying the position of the operator compared to the stabilisers, so they only open if the operator is positioned to see their movement properly.

The crane features the DLC-S stabilisation program. Using the remote control operators can simulate the stabilisation capacity that the crane will have in a certain position and with the stabilisers opened. This is a great feature to plan the scheduled lifts.