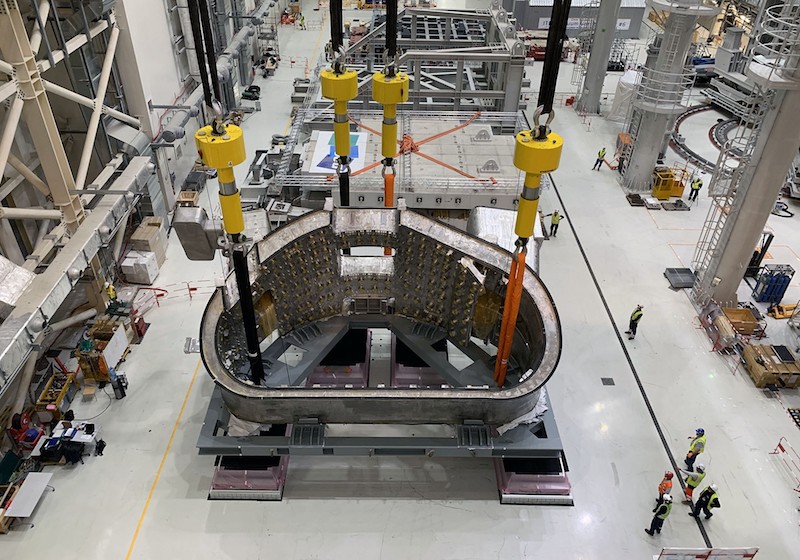

Enerpac SyncHoist lifting systems are assisting in the assembly of the Vacuum Vessel for ITER in Southern France. The SyncHoist millimetre lifting accuracy is needed to lift 500 tonnes vacuum vessel sectors into an Up-Ending tool for vessel assembly by the ITER Sector Sub-Assembly Tool. The torus-shaped ITER vacuum vessel will host the fusion reaction. Within this vessel, plasma particles collide and release energy at temperatures up to 150M degrees C without touching any of its walls due to a process of magnetic confinement. The vacuum vessel comprises nine sectors made of special grade stainless steel. Each sector is 13 metres high, 6.5 metres wide and 6.3 metres deep.

The Enerpac SyncHoist system comprises four, double acting, push-pull cylinders connected to lifting points. As the Centre of Gravity (CoG) for each vacuum vessel sector may vary from the theoretical, four 225 tonnes lifting capacity Enerpac SyncHoists are used to assess the CoG and ensure the lifting of each sector is as close to the plane as possible. Each vacuum vessel sector is delivered to ITER on a rigging platform. A SyncHoist is connected to each of the platform’s four lifting points allowing millimetre control at each point. The SyncHoists are arranged in pairs suspended from header beams connected to the ITER assembly hall’s overhead crane for the 10m lift to the Up-Ending Tool.

“It is essential that we hold the vacuum vessel sector in the plane during lifting. SyncHoist allows us to know the load at each lifting point and control the lift precisely with a 1mm accuracy,” says Jarl Buskop, assembly engineer, Sector Modules Delivery & Assembly Division, ITER. “Another benefit of using SyncHoist to cope with variations in the Centre of Gravity is the ability to lift the vacuum vessel sector clear of its surrounding transportation frame where there is only 15-30mm clearance for the rigging platform.”

To meet the ITER project requirements, each of the 1000mm stroke SyncHoists hydraulic lifting systems was made completely leakproof. In addition to the vacuum vessel sectors, the SyncHoist lifting system will be used to lift toroidal magnet field coils for insertion in the vacuum vessel.