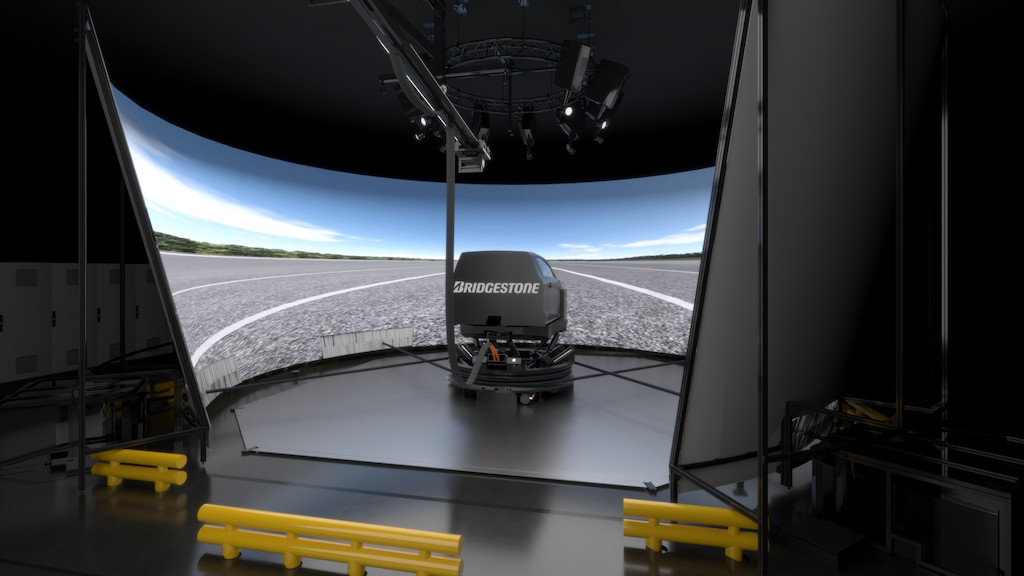

Bridgestone has announced a major investment in a Driver-in-the-Loop (DiL) simulator at its EMEA R&D Centre near Rome, Italy. This technology enhances the company’s Virtual Tyre Development (VTD) capabilities, marking a significant step toward fully digitalizing the tyre development process.

By integrating AI-driven tyre and vehicle simulations, Bridgestone aims to accelerate innovation, improve sustainability, and shorten development cycles. The new DiL simulator allows engineers to virtually test tyre performance in various conditions, combining real-time feedback from expert drivers with physics-based simulations. This speeds up the evaluation of new design concepts, ensuring optimal performance before physical prototypes are created.

A key sustainability advantage of the new simulator is its potential to significantly reduce material waste and CO2 emissions. Bridgestone estimates that up to 12,000 experimental tyres will be saved annually, decreasing environmental impact. The company’s existing VTD technology has already cut raw material consumption and CO2 emissions by up to 60% for Original Equipment (OE) tyre development and at least 25% for replacement tyres.

Expected to be fully operational by the end of 2025, the VI-grade dynamic driving simulator will initially focus on assessing dry handling, with plans to expand into other performance areas. Bridgestone anticipates that up to 50% of its OE developments will incorporate DiL simulation annually.

“This investment is a milestone in our journey toward a comprehensive digital ecosystem for tyre innovation,” said Emilio Tiberio, Chief Technology Officer of Bridgestone West. “It strengthens our R&D capabilities while supporting our commitment to sustainability and efficiency.”

Bridgestone, a leading global investor in R&D, allocates over €800 million annually to technological advancements, reinforcing its pledge to innovation and sustainable mobility.