Palfinger has introduced an innovative tiltable crane fork, designed to optimize material transport in construction, logistics, and infrastructure projects. Available on the European market for the first time in January 2025, this solution is fully integrated with the overload function of Palfinger TEC Loader Cranes, ensuring enhanced safety and efficiency.

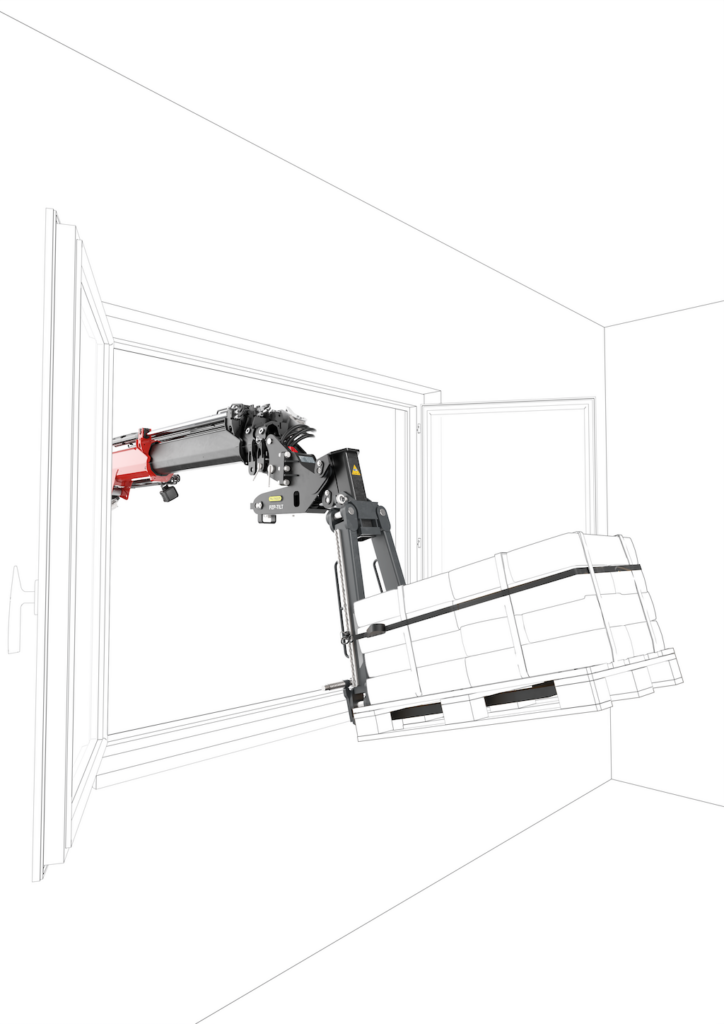

The tiltable crane fork is ideal for lifting both palletized and non-palletized materials to great heights, especially in tight, hard-to-reach areas like upper floors or through façade openings such as windows and doors. Its thoughtful design allows for quick and easy mounting on all TEC loader crane models with PALTRONIC 180, making it an invaluable tool for projects requiring precise and efficient material transport.

One of the key benefits of this crane fork is its ability to eliminate the need for disassembly work on railings, cladding, or the use of temporary platforms. By positioning loads through the smallest openings, it saves valuable time and effort. Moreover, the system’s precise hydraulic tilt control and integrated strap for securing loads offer increased flexibility, ensuring that materials are transported safely, regardless of size.

Safety is a top priority with the Palfinger tiltable crane fork, as it is the first solution on the European market to meet the EN12999 standard for loader cranes. The specially developed MTCF software function integrates the fork into the crane’s overload system, providing active warnings in case of overload and allowing only movements that reduce the load moment. This prevents accidents, protects the crane, and improves its overall availability.