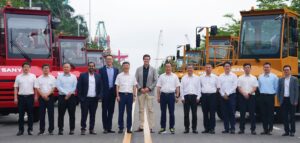

Sany heavily invests in the research and development of vehicles and machines with alternative drives. In China and Southeast Asia, 100 electric Sany empty container handlers and 40 reach stackers are already being used. The manufacturer is now bringing its environmentally-friendly port machinery to Europe.

The EU has set an ambitious target of reducing greenhouse gas emissions by at least 55% by 2030. The transport and industrial sectors play a crucial role in achieving this goal, and the type of drive is a significant factor when purchasing new port machinery. With the use of regenerative electricity, complete emission-free operation can be achieved with fully electric machinery. Jürgen Keller, product manager at Sany Europe, explains: “Many customers are aware they need to change their machinery purchases quickly if they are to significantly reduce CO2 emissions across their fleet by 2030 and comply with EU requirements for reduced emissions. At customer level, I expect to see more discussions about this in the next 6-12 months.”

Available in Europe from 2023

The practical experience that Sany has gained in Asia has been incorporated into the continued development of its machinery. In addition to excavators and trucks, everyday use of electric empty container handlers, reach stackers, and terminal tractors has become common. Adherence to European standards and operator habits, combined with successful certification, have paved the way for electric port machinery in Europe. The machinery is set to be delivered in H1 2023.

Smart Charging, Longer Driving

One of the major challenges for electric machinery is the recharging process. Operators aim to have as much operating time as possible, which translates to smart charging. One solution is opportunity charging, such as by setting up charging stations in the canteen area. The batteries can be charged while the operator takes a coffee break, and 10-15 minutes of charging is enough to regain sufficient power for the next task. Longer charging can then be performed during lunch breaks.

Sany also offers a hybrid reach stacker to reduce emissions by 20%. The combination of two drive types, combustion engine and simple hydro-pneumatic drive, make it possible. Additionally, Sany’s mobile port machinery that is equipped with a Stage V engine can run on both biofuels and conventional fuels.