United Heavy Lift has added two Eco-Lifter newbuildings to its fleet. This commitment goes hand in hand with UHL’s newly developed long-term ESG strategy: “One of our goals is to reduce emissions from our own operations and help our clients achieve their decarbonization goals. Sustainability is an integral part of how UHL operates. Key to this change is to build and maintain one of the most modern and fuel-efficient MPP heavy lift fleets in the market. We are phasing out all UHL 800 P-type vessels and replacing them with fuel-efficient modern tonnage. Our vision is to become a sustainability leader in the heavy lift industry.” says Andreas Rolner, managing director of United Heavy Lift.

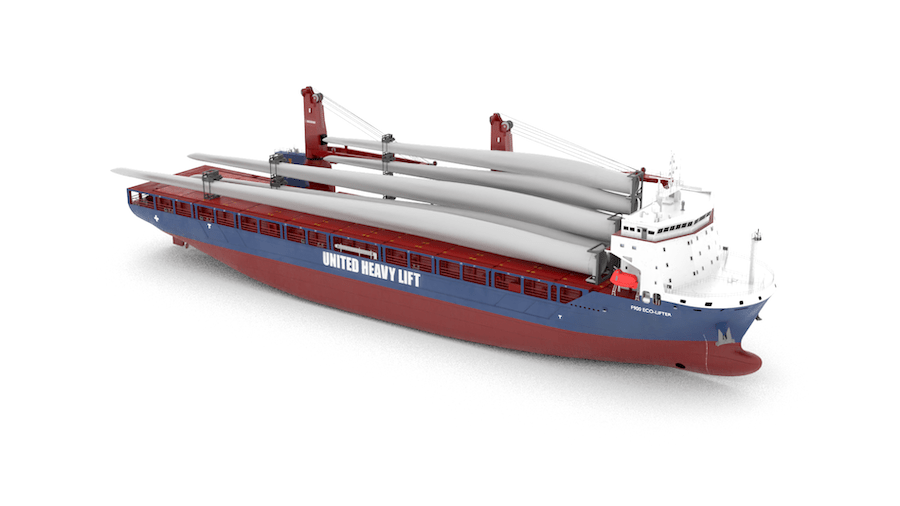

Between 2019 and 2022, UHL took delivery of seventeen state-of-the-art F900 Eco-Lifters newbuildings, which are already raising the standard for eco-friendly breakbulk and heavy lift ocean transport. UHL operates a fleet of over 20 vessels with lifting capacities of up to 900 mtons. With a fleet of over 20 vessels, UHL has relatively full order books the coming years.

The new F900 Eco-Lifter class features high- and low-pressure SCR catalysts to meet IMO Tier III requirements. With minimized CO2 emissions, the vessel class exceeds latest EEDI benchmarks. UHL will be taking delivery of the two F900x Eco-Lifter newbuildings at the CSSC shipyard in Hudong, China in 2023 and 2024.

Once the Eco-Lifter newbuilding program is completed, UHL will service its clients with a fleet of nineteen F900 Eco-Lifter vessels. “The carbon footprint of the F900 class is 30-50% less compared to the existing heavy lift fleet in the market.” states Mr. Bonnesen, managing director of UHL.